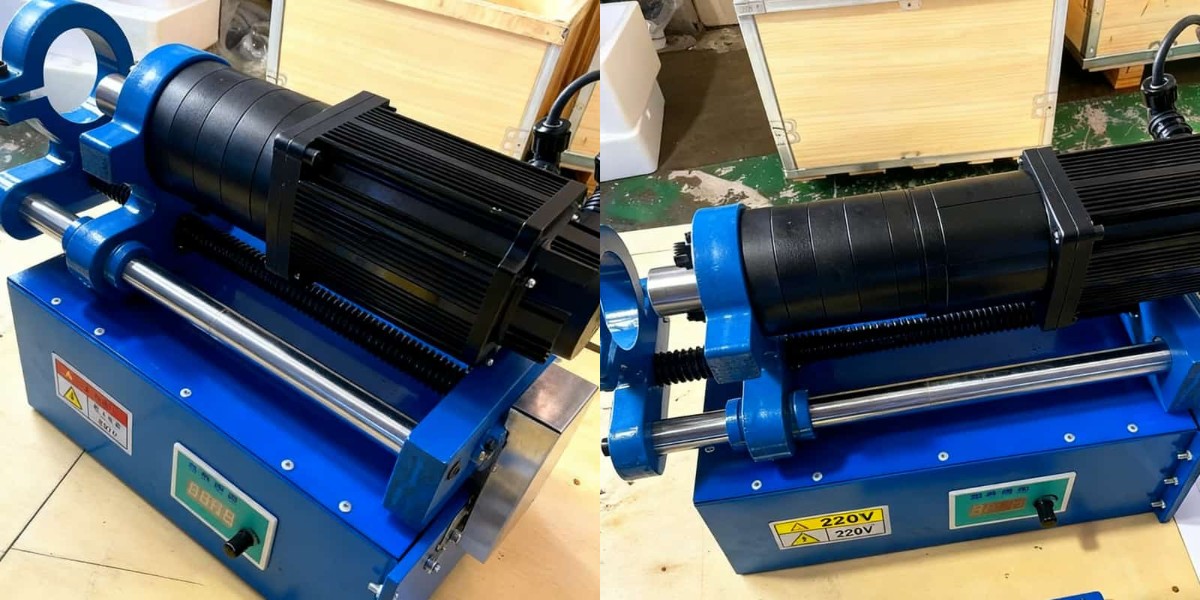

Portable cylinder boring machine

Easy Operation Advantage: Quick to get started, with a simple operation process, enabling fast operation without complex training.

Good Stability Advantage: Stable structure, smooth operation, and guaranteed precision stability during the processing.

Time and Labor Saving Advantage: Efficient operation, significantly reducing processing time, lowering labor costs, and improving production efficiency.

Overview

This portable boring bar machine is equipped with a powerful power system, delivering excellent processing efficiency. With years of industry experience, our company strictly controls quality throughout the R&D and production process, ensuring the portable engine boring bar machine boasts stable performance and outstanding precision. It provides reliable, efficient and professional solutions for various portable line boring bar machine operations.

Specifications

Welding range | 40-300mm |

Spindle speed stepless speed | 0-22r / min |

Width | 280mm |

Power | 100W |

Axial stroke | 0-280mm |

Voltage | 380V/220V |

Product Advantages

Precise Boring Advantage: High processing accuracy with controllable boring results, meeting the requirements of precision operations.

Compact Size Advantage: Compact and portable design, saving storage space and suitable for multi-scene operations.

Durability Advantage: Made of high-quality materials with a reliable structure, featuring a long service life and reducing maintenance costs.

Application Scenarios

This mobile boring machine is specially designed for repairing out-of-round shaft holes of construction machinery and ships. It is suitable for excavators, cranes, hoists and other equipment, and can also accurately repair related shaft hole faults of ships, efficiently solving the problem of shaft hole out-of-roundness and ensuring the stable operation of equipment.

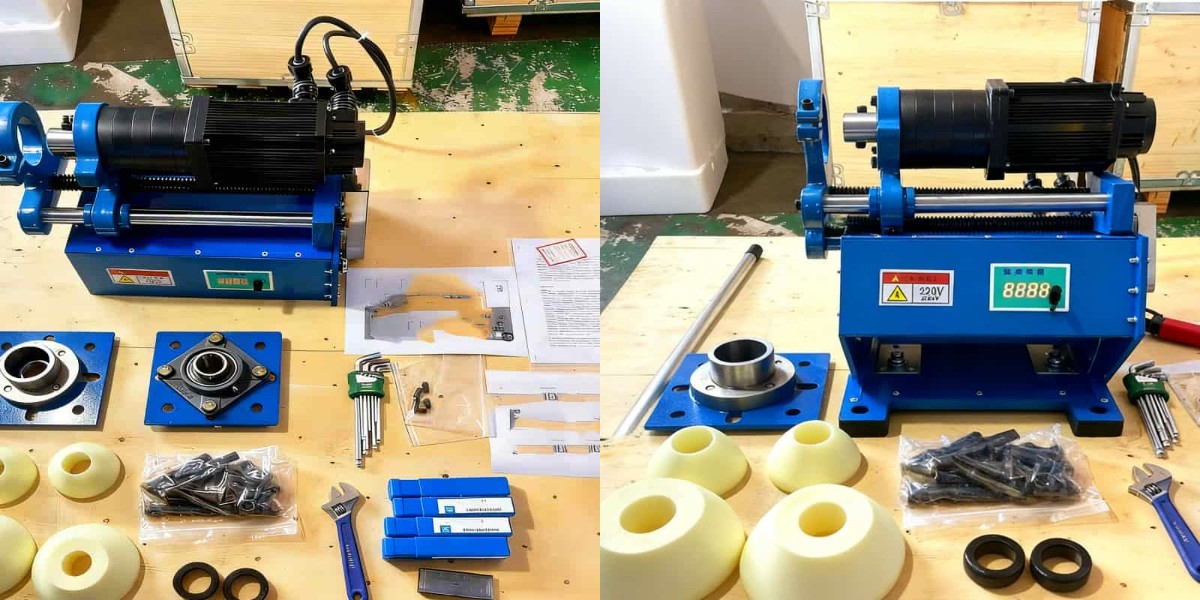

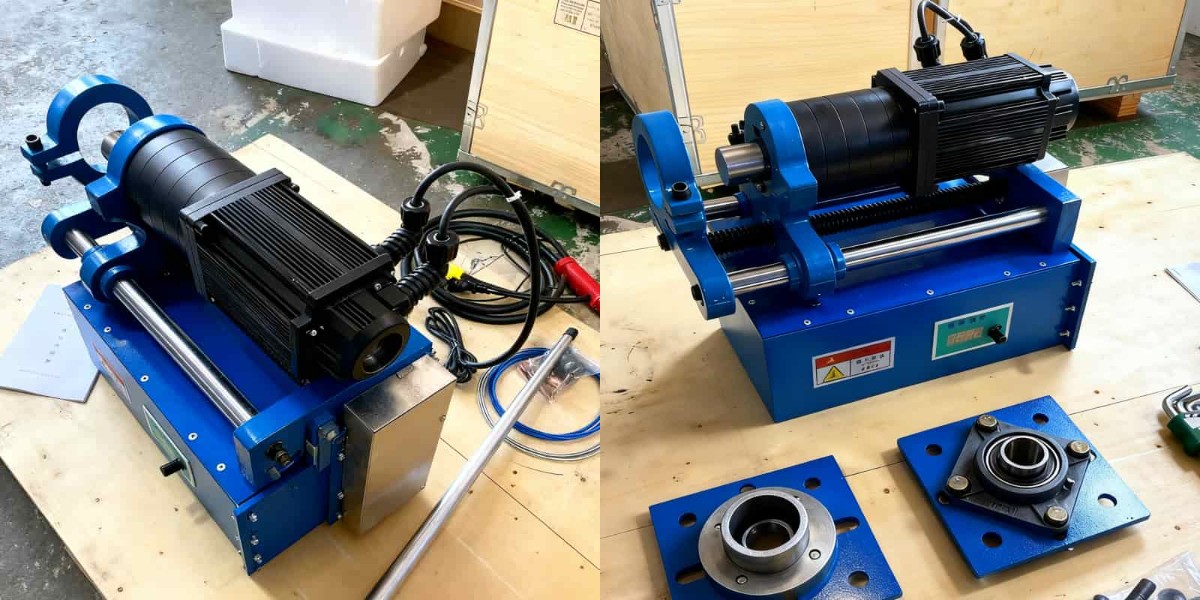

Shipping Site

At the shipping site of our boring machine, the equipment and accessories (including motors, cables, tools, etc.) are all properly packed in wooden cases with adequate protection. Operation instructions and quality inspection documents are included with the shipment. The logistics process is rigorous to ensure the equipment is delivered to customers in good condition, facilitating efficient shaft hole repair operations in fields such as construction machinery and ships.

Customer FAQs

Q: Is the quality of this boring machine guaranteed?

A: Strict quality control throughout production, combined with high-quality materials and mature craftsmanship, ensures stable and reliable performance.

Q: What after-sales services can I enjoy after purchase?

A: Professional after-sales support is provided, including installation guidance, troubleshooting and maintenance services, to address usage concerns.

Q: Is customized service available?

A: Personalized customization services can be offered based on the needs of different scenarios such as construction machinery and ships.

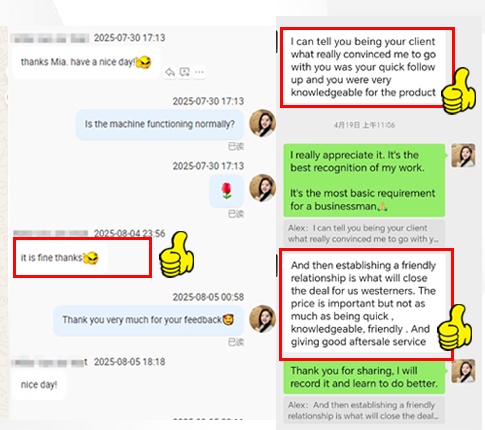

Customer feedback

Genuine testimonials from customers who purchased our cnc boring and welding integrated machine: Whether it's bulk purchasing or customized needs, we earn recognition with our capabilities and gain trust with our service.

After-sales Service

We offer comprehensive after-sales service for worry-free use. 24/7 online support in Chinese, English, Spanish, French, German, Russian, etc., with professional technical guidance. 1-hour response to machine malfunctions. Detailed installation videos for quick setup. Logistics options include sea freight, DHL, FedEx, with real-time tracking. New machine or spare parts provided for non-human damage.