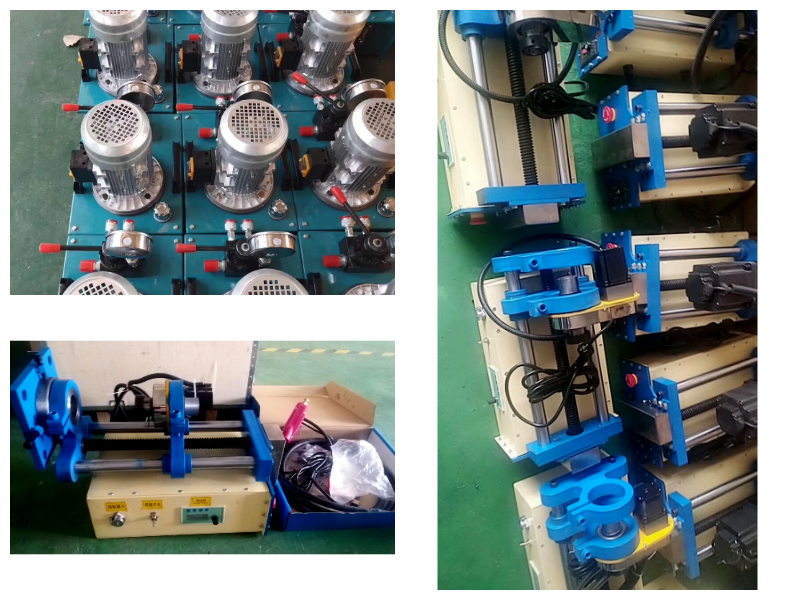

Line Boring Machine Portable

Powerful Functionality & Wide Applicability

Versatile Machine: Capable of not only boring and milling but also grinding and polishing with optional attachments. A one-stop solution for on-site machining tasks including drilling, facing, and grooving.

Broad Application Range: Ideal for on-site repair and manufacturing of key components on excavators, cranes, loaders, and other machinery, such as pin holes, engine bores, hydraulic cylinder tubes, and bracket holes.

Horizontal Boring Machine Core Features & Advantages:

Rigid & Stable Design: Manufactured from high-strength materials to minimize vibration, ensuring precise cuts and superior surface finishes even in tough conditions.

High Precision Machining: Guarantees restored bores with tight tolerances, excellent concentricity, and correct geometry, extending the life of the new pin and the assembly.

Portable & On-Site Capability: Enables high-quality repairs to be performed in your workshop or directly on-site, eliminating the need for disassembling and transporting entire machine structures.

Ease of Use & Setup: Designed with the technician in mind, featuring user-friendly adjustments and secure mounting systems for various applications.

Cost-Effective Maintenance: A vital tool for equipment owners and repair shops, offering a cheaper and faster alternative to replacing entire components or structures.

Technical Specifications

Main motor power: 1.5KW, stepless speed change (0--180 rpm).

Feeding box: stepless speed regulation, automatic feeding.

Tool feeding motor: 220V, 120w stepless speed regulation

Boring range: diameter 45mm-200mm.

Boring bar specification: 40mm*1500mm (can be customized according to customer requirements)

Boring bar material: 45 #.

Boring bar processing process: quenching and tempering, turning, quenching, grinding, and surface plating.

Feed guide rail: double cylindrical guide rail (45#steel, quenched and tempered, turning, quenching, grinding, hard chromium plating).

Cutting feed rate:zui small 0.10mm/revolution.

Maximum cutting amount: 2mm on one side.

Working stroke: 300mm (can be customized according to customer requirements)

Weight: 60 kg