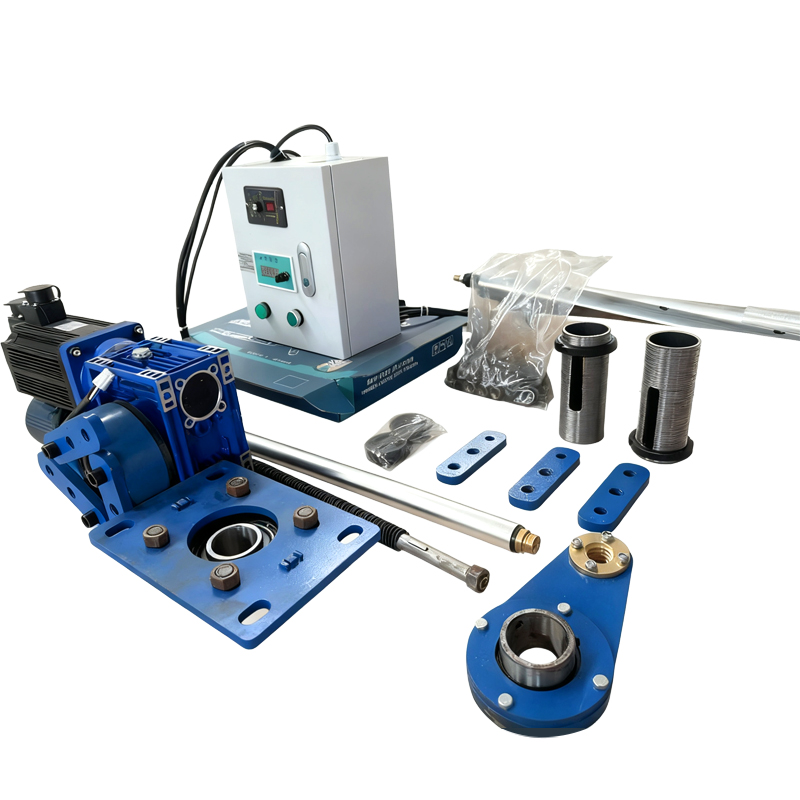

Portable boring bar machine

Integrated Efficiency: 1 clamping for 2 processes (boring, welding); no repeated workpiece disassembly, boosting processing efficiency & coaxial accuracy.

Flexibility: Compact, lightweight modular design—easy to transport, fits narrow spaces, enables on-site quick repair/manufacturing of large workpieces.

Smart Operation: User-friendly CNC system + stable parameters; simplifies complex operations, ensures consistent high-quality results.

Description

This portable line boring bar combines precision boring and efficient welding. Compact and lightweight, it's ideal for on-site manufacturing and repair of large workpieces. The portable line boring built-in stable wire feeding system ensures welding quality, enabling one-time completion of positioning, boring and welding—greatly boosting processing efficiency and coaxial accuracy, and serving as a reliable solution for complex on-site conditions.

Specifications

Item | Specification |

Main Motor Power | 1.8 kW, stepless speed control (0–180 RPM) |

Feed Box | Stepless speed regulation, automatic feed |

Feed Motor | 220V, 120W, stepless speed control |

Boring Diameter Range | Ø80 mm – Ø180 mm |

Boring Bar Specification | 40 mm × 1500 mm (customizable upon request) |

Boring Bar Material | 45# steel |

Boring Bar Processing | Tempered, turned, quenched, ground, surface hard chrome plated |

Feed Guide Rail | Double cylindrical guide rails (45# steel, tempered, turned, quenched, ground, hard chrome plated) |

Minimum Cutting Feed | 0.10 mm/rev |

Maximum Cutting Depth | 2 mm (per side) |

Working Stroke | 300 mm (customizable upon request) |

Weight | Approx. 60 kg |

Product Features

Smart CNC System: Digital-display CNC host, user-friendly interface, precise boring/welding parameter adjustment, ensuring processing consistency.

Modular Precision Components: Various boring heads, bearing blocks, tooling fixtures; fits different workpiece sizes, flexible on-site assembly/disassembly.

Stable Wire Feeding & Accessories: Built-in wire feeding system + full welding accessories (e.g., contact tips, wire); ensures welding quality, enables integrated boring-welding.

Product Details

Thickened Support Seat: Stabilizes the boring bar, prevents tool vibration, and reduces machining errors.

High-Strength Screw Rod: Manual-automatic integrated feed design ensures smooth and stable operation.

Alloy Positioning Block: Durable, wear-resistant, easy to disassemble and use. Together, they ensure machining precision and operational efficiency.

Packaging and Shipping

Thickened solid wood case with internal EPE foam cushioning to avoid bumps and collisions.

External reinforced steel straps and anti-slip pallets for easy handling, anti-falling, plus shipping warning labels to keep equipment intact throughout transit.

Company Strength Exhibition

Our company owns a modern factory of Shandong Jiesheng Machinery, equipped with professional production and quality inspection workshops, enabling efficient mass production of boring and welding machines. Advanced production equipment and a strict quality control system ensure the reliability of each machine, supporting our foreign trade business in stably supplying high-quality products to global customers.