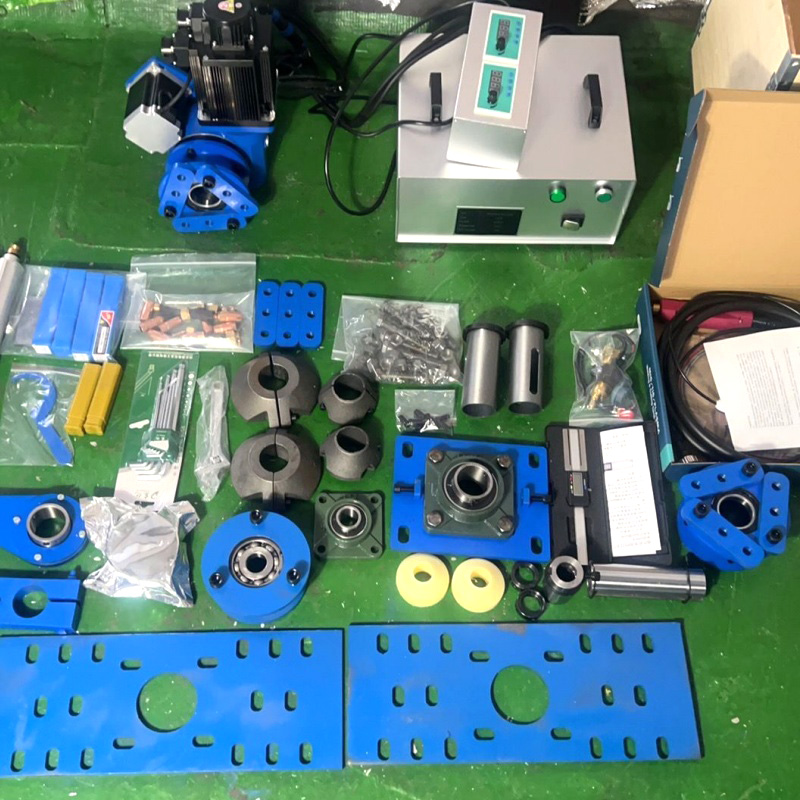

Line bore welder

Lightweight & Portable for Complex Scenarios: High-strength lightweight material, easy to carry, fits narrow/complex sites.

2-in-1 Function, Higher Efficiency: Integrates high-precision boring & welding, reduces process switching.

Easy Operation, Low Threshold: Intuitive interface, beginners ready after short training.

Overview

This portable line boring welding machine is an efficient processing equipment combining boring and welding functions with outstanding advantages. Made of high-strength lightweight materials, it’s easy to carry and fits narrow, complex workplaces.

The bore welding machine boasts ±0.02mm high-precision boring for various needs, supports multiple welding methods for efficient, high-quality welding. With an intuitive interface, beginners can operate it after short training. The boring and welding machine integrated mode cuts process switching and boosts efficiency.

Specifications

Item | Specification |

Main Motor Power | 1.8 kW, stepless speed control (0–180 RPM) |

Feed Box | Stepless speed regulation, automatic feed |

Feed Motor | 220V, 120W, stepless speed control |

Boring Diameter Range | Ø80 mm – Ø180 mm |

Boring Bar Specification | 40 mm × 1500 mm (customizable upon request) |

Boring Bar Material | 45# steel |

Boring Bar Processing | Tempered, turned, quenched, ground, surface hard chrome plated |

Feed Guide Rail | Double cylindrical guide rails (45# steel, tempered, turned, quenched, ground, hard chrome plated) |

Minimum Cutting Feed | 0.10 mm/rev |

Maximum Cutting Depth | 2 mm (per side) |

Working Stroke | 300 mm (customizable upon request) |

Weight | Approx. 60 kg |

About Us

We always select high-quality raw materials to control quality from the source. We strictly follow production processes and quality control standards to ensure every product has excellent quality and stable performance. All products have successfully passed CE certification, fully complying with international market standards, and providing you with solid and reliable quality assurance for your procurement and use.

Client visit

On October 7, 2025, two Australian clients made a special trip to our factory to conduct an on-site visit and inspection of the production process and performance of our boring-welding integrated machines. After a detailed understanding and on-site experience, the clients highly recognized the high precision, high stability and efficient operation capability of our machines, and confirmed the purchase order on the spot, successfully ordering a batch of equipment.