Portable Line Boring

Precision Machining: Delivers Ra ≤ 3.2 surface finish and ≤ 0.02 mm roundness error.

Portable Field Use: Lightweight and modular design supports rapid on-site setup.

High Durability: Alloy boring bar undergoes heat treatment and chrome plating for extended life.

Flexible Boring Range: Accommodates bore diameters from 45mm to 160mm with optional facing support.

Customizable Stroke: Maximum 300mm travel, adjustable upon request to fit specific jobsite needs.

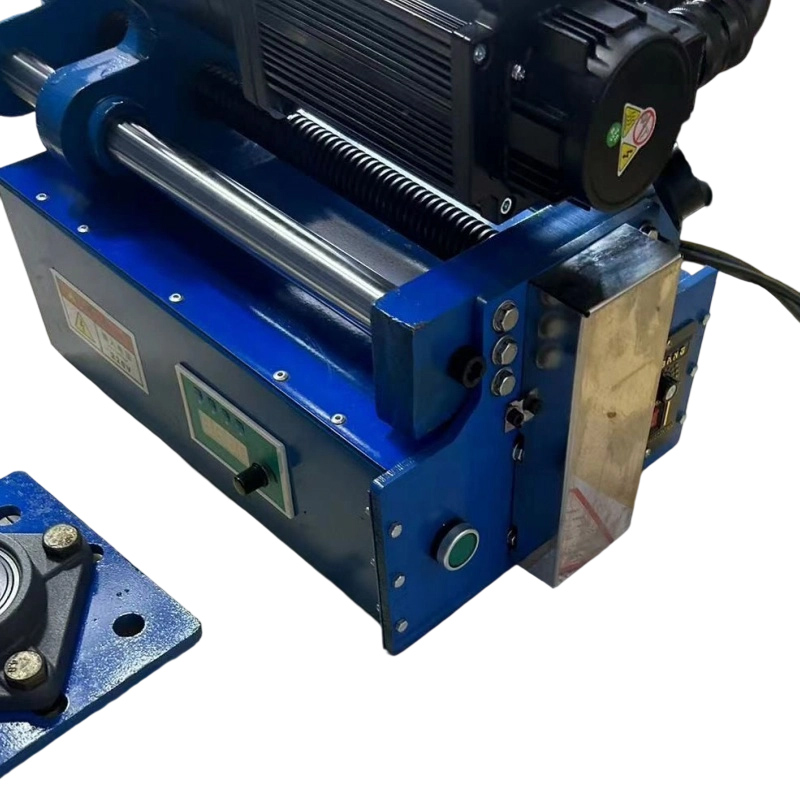

The Boring Machine 40–200 is a portable on-site machining solution designed for high-precision repair and reboring of shaft pin holes, hinge holes, and rotary holes in heavy-duty construction equipment. It is ideal for excavators, loaders, cranes, and hydraulic presses, especially for concentric hole repairs and sleeve insertion after reaming.

Engineered for durability and high-performance machining, this portable boring machine is installed using a bolt-and-weld clamping system, allowing quick disassembly and effortless transport. With continuous cutting, high efficiency, and tight tolerance machining, it is a perfect choice for field repairs that demand both speed and accuracy.

Key Features

Versatile Machining Capabilities: Supports boring, welding repair, and sleeve installation on diameters ranging from 45mm to 160mm.

Stepless Speed Control: Spindle and feed systems feature continuously adjustable speeds for optimal cutting performance.

Robust Build Quality: The boring bar and guide system are crafted from heat-treated alloy steel, offering outstanding wear resistance.

Compact & Portable: Easy to transport and assemble on-site, ideal for field operations and emergency repairs.

End-Face Machining Optional: Supports expansion to perform facing or flat-end boring operations as required.

Technical Specifications

| Parameter | Value |

Minimum Boring Diameter | 45 mm |

Maximum Boring Diameter | 160 mm |

Max Stroke | 300 mm (customizable) |

Max Cutting Depth (per side) | 2 mm |

Surface Roughness | Ra ≤ 3.2 |

Roundness Accuracy | ≤ 0.02 mm |

Spindle Rotation Speed | 0–80 RPM |

Equipment Weight | Approx. 60 kg |

Power Requirement | 220V spindle motor, 380V power input |

Structure & Components

Spindle System: Driven by a 220V low-speed, high-torque motor with forward/reverse/neutral control.

Feed System: End-mounted control with adjustable feed gears (1/0/2 positions) and dial-based feed rate adjustment.

Boring Bar: 40mm diameter alloy steel bar, heat-treated and chrome-plated for hardness, straightness, and anti-fatigue performance.

Tool Holder: Adjustable along the full effective stroke. Suitable for bore sizes of 45–160mm using interchangeable holders.

Support Base: Weld-on bracket and alignment system allowing axial movement and precision placement during operation.

Electric Control Cabinet: Integrated with delay-brake controller to prevent vibration upon stopping.

Applications

The 40–200 Boring Machine is purpose-built for industries including:

Construction Equipment Maintenance

Heavy Machinery Repair

On-Site Machining Services

Sleeve Bushing Installation After Reaming

Excavator arm holes, loader hinge points, rotary joints.

Pin and sleeve hole recovery for hydraulic presses and cranes.

Ideal for mobile repair teams handling field refurbishments with strict tolerance requirements.

Its portability and customization options make it an ideal tool for industrial field servicing, especially in environments with limited access to workshop machines.