Portable Boring Machine for Sale

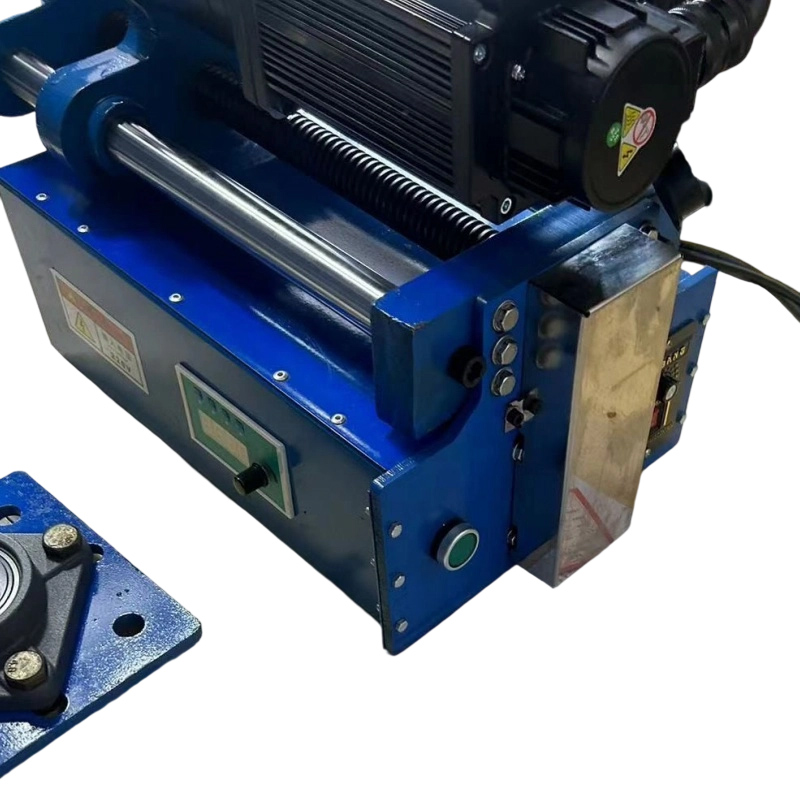

1. High precision and high quality machining: extremely high rotational precision, accuracy ±0.01mm, meets the stringent industrial standards. Stable double cylindrical guideway and rigid body design ensure the stability of the machining process and repeatable positioning accuracy. Accurate hole size and smooth hole wall.

2. Powerful processing capability and adaptability: Boring diameter covers the boring needs from small precision holes to large workpieces (such as concentric holes for excavators, loaders, presses, cranes, etc.).

3. Durability and long-term stability: high-quality materials and structure: the main components are made of high-quality materials to ensure the rigidity and stability of long-term use and resistance to deformation.

Boring machine for construction machinery is a kind of on-site machining equipment mainly used for machining and repairing small and medium-sized pipes and shaft pin holes. It is a standing tool in construction machinery maintenance industry Widely used in various construction machinery. Machining and repair of pin hole, rotary hole, main arm connection hole and lifting ring hole after welding Machining and repair of concentric holes in excavator, loader, crane, crawler crane and large offshore crane; One positioning installation can ensure the concentricity of multiple holes

Product Detail

Construction Machinery Boring Machine is used for various construction machinery structure on the shaft pin hole, slewing hole, articulation hole after welding processing, or reaming set, excavators, loaders, presses, cranes and other concentric hole repair and processing.

Boring machine adopts welding and bolt connection fixed clamping installation, easy to dismantle and transportation, 40 boring machine is suitable for a variety of concentric holes, side by side multiple holes processing. The work is continuous cutting, high productivity and high machining precision.

Machine parameter

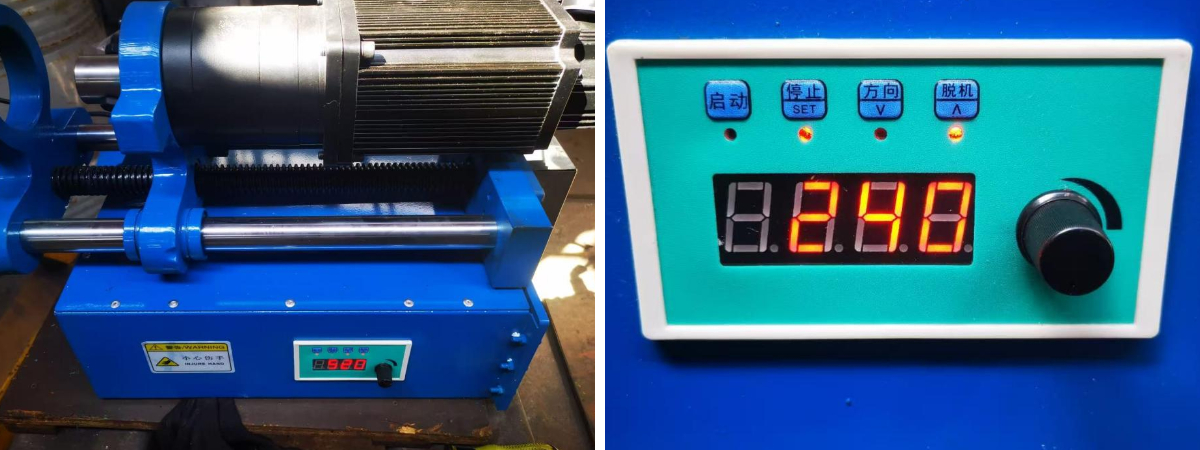

Main motor power | 1.5KW, stepless variable speed (0--180 rpm) |

Feed box | infinitely variable speed, automatic feeding |

Walking tool motor | 220V, 120w infinitely variable speed |

Boring range | diameter 45mm-200mm |

Boring bar specification | 40mm*1500mm (can be customized) |

Boring bar material | 45# |

Boring bar processing technology | tempering, turning, quenching, grinding, surface hard chrome plating |

Feed guide | double cylindrical guide (45# steel, tempering, turning, quenching, grinding, hard chrome plating). |

Cutting feed | Minimum 0.10mm/rev |

Maximum cutting capacity | 2mm on one side |

Working stroke | 300㎜(can be customized) |

Weight | about 60kg |

Positioning cone sleeve | aperture 40 mm, 4 pieces. |

Adjustable support frame | 1 set (2 before and 2 after). |

Tool holder | 1 set (processing aperture 90-130mm 1, 130-180mm 1). |

Cutting tools | 4 (W1 2 2, 2 HSS). |

Hexagon socket wrench | 1 set. |

10 "adjustable spanner | 1 set. |

Top silk | M8*10mm4, M8*25mm4. |

Coupling bolt | M10*65mm1. |

Packing cases | 2 (1 main machine, 1 boring tool bar). |

Random data | 1 set (operation manual and qualification certificate) |

Machine Picture

Complete accessories

It is equipped with different types of blades and adjustingknives for the convenience of customers

Main application range

Repair welding of rotating holes, hinged holes and shaft pin holes on various constructionmachinery structures, or install hole sleeves after reaming; Excavator,The loader, press,crane is equivalent to the repair and processing of the core hole, the hole side by side, thehole for one-time positioning processing, to ensure the porosity of the coaxial.

Service

(1) Punctual: Have your orders met with the latest delivery? We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20year production experience. We have over 20 years exprerience in this industry. That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service There is two sales departments who will serve you from inquiry to products shipped out.

During the process, you just need to discuss with him for all the problems and the way sames much times.