Portable Shaft End Lathe

Ultra-High Precision: Capable of achieving sub-micron level accuracy and superior surface finish.

Strong Material Compatibility: Effectively machines tough materials like quenched steel and hard alloys.

Post-Treatment Correction: Accurately corrects deformation from heat treatment to meet final tolerance.

Versatile & Stable Design: Rigid frame with precise guide and spindle system ensures consistent results across various applications.

Automation-Ready: Easily integrates with modern automation systems for loading, measuring, and production efficiency.

The portable external circle machining machine is a compact and highly efficient device specifically designed for external cylindrical machining. It is primarily utilized for processing outer circles, short shafts, chamfers, and bearing journals or seats. This equipment is suitable for both horizontal and vertical operations and is ideal for on-site maintenance and machining of internal components made from materials such as steel, copper, stainless steel, and others.

Product Details

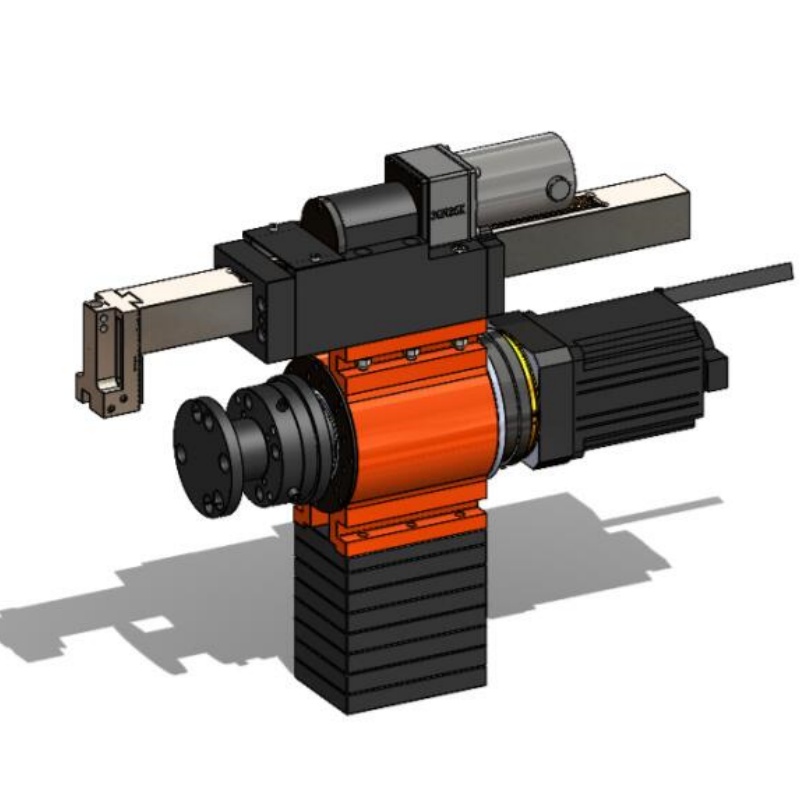

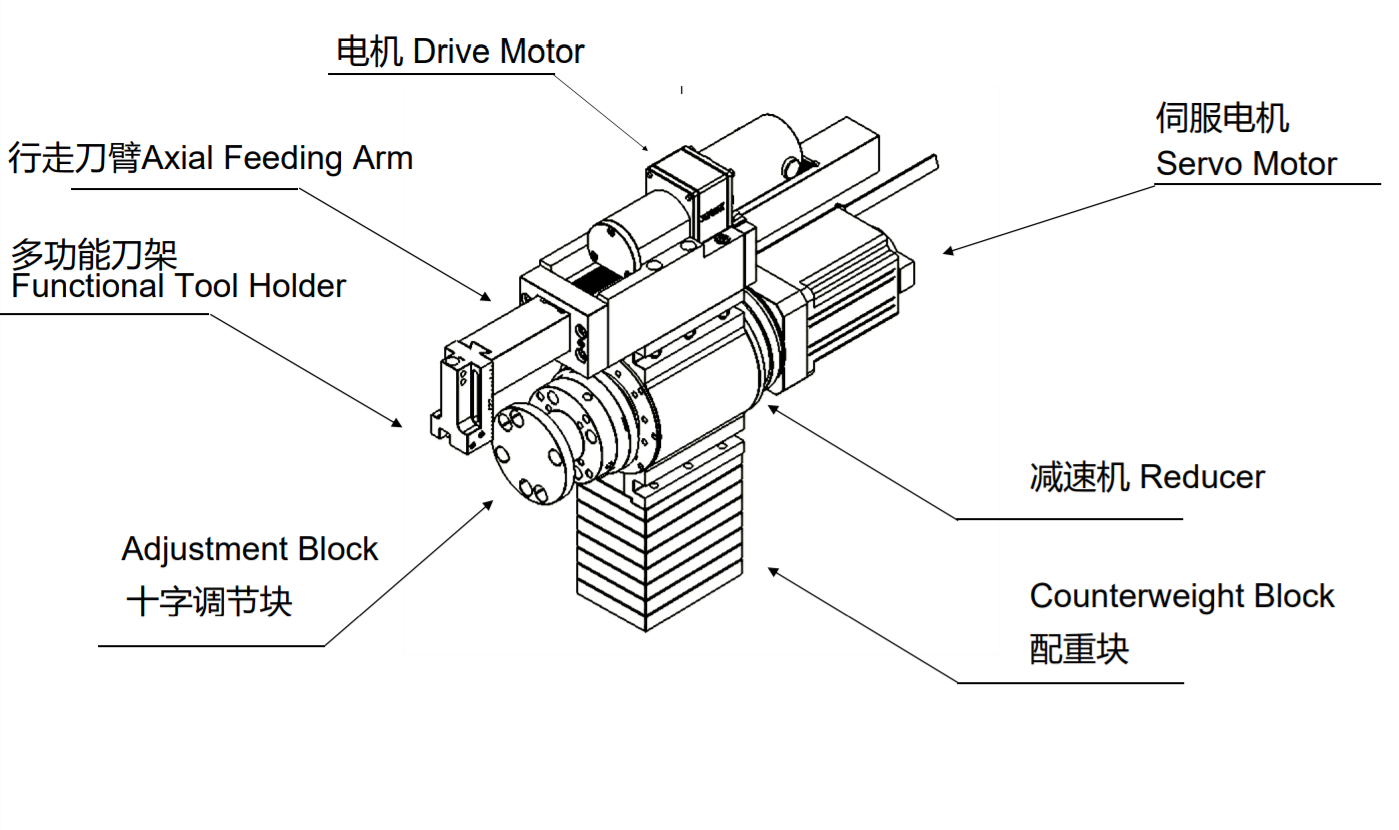

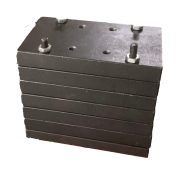

External Circular Processing Machine

The outer circle machining machine delivers micrometer-level or even sub-micrometer precision, thanks to its high-accuracy capabilities. It achieves an excellent surface finish, significantly minimizing the need for secondary polishing. This machine excels in machining hard-to-process materials like hardened steel and hard alloys, which are typically challenging for conventional lathes. Its high-precision correction function allows accurate reshaping of components after heat treatment, ensuring final dimensional accuracy. It features a rigid, stable structure, precision linear guides, and a high-quality spindle system to guarantee consistent machining, high repeatability, and versatility. The machine is capable of processing various external cylindrical surfaces, conical sections, end faces, stepped shafts, and crankshaft journals. Additionally, it can be easily integrated with automated systems such as auto loading/unloading units and measurement compensation modules, facilitating efficient and automated production.

Model | JS-WY-80 |

Processing range | 80-230mm |

Processing length | 300mm |

Machine speed | 0-150 rpm |

Motor power | 1.8KW |

Feed speed | Stepless speed regulation |

Drive selection | Servo motor |

Fineness | R3.2 |

Ellipticity | 0.02mm |

Taper | 200/0.03mm |

Maximum machining capacity | 1.5mm |

Function | Cylindrical turning,cylindrical welding |

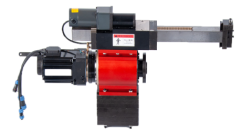

Machine pictures

MACHINE LIST

Host | Main control box | ||

Soldering wire | Split screen control box | ||

Welding drive motor | Adjustable knife holder | ||

Universal adjustment block | dial indicator | ||

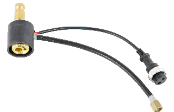

clump weight | Adapter | ||

calipers | Protect the mouth | ||

Conductive nozzle |

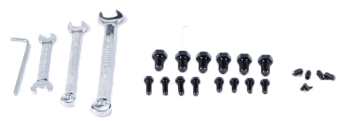

| tool kit | |

cutter bar | Knife grain | ||

SERVICE

Pre-sale Services

Offer free equipment consultation

Provide standard machine configuration and process flow diagram

Deliver tailored solutions and free design based on client-specific requirements to assist in equipment selection

Services During Sales

24/7 online service available in Chinese, English, Spanish, French, German, and Russian, including technical support

In the event of a malfunction, our team ensures resolution within one hour

Supply machine installation instructional videos

Offer full logistics updates, including sea freight, express services (DHL, FEDEX), and real-time tracking

In case of non-human-caused damage, replacement machines or parts will be supplied free of charge