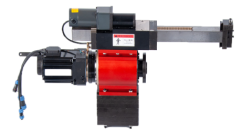

External Circular Processing Machine

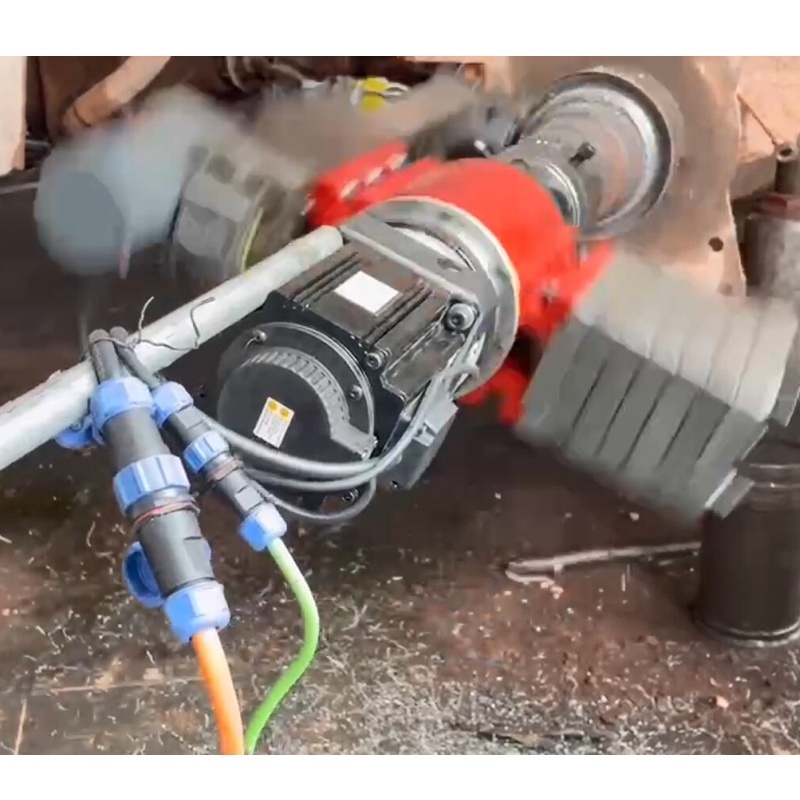

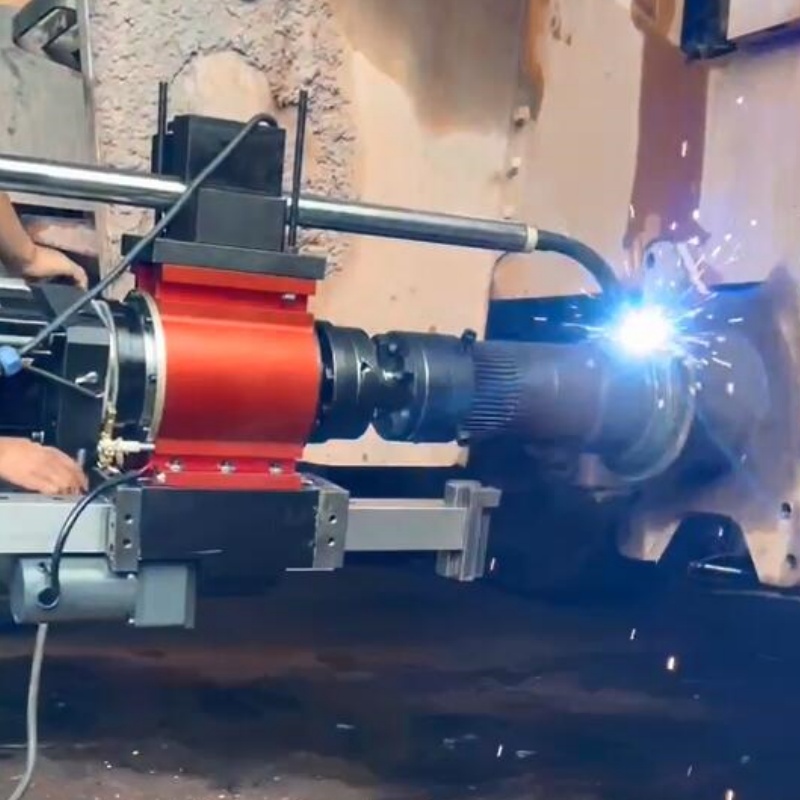

Automatic Operation: This Portable Journal Lathe Shaft Turning Truck Repair Shaft Repair Field Service 220V/380V Automatic Turning & Welding Machine features automatic operation, allowing for efficient and hands-free processing of various tasks.

High-Speed Performance: With a range of spindle speed of 150 r.p.m, this machine is designed to handle high-volume production and heavy-duty applications in machinery repair shops and construction works.

Multi-Axis Capability: Equipped with 2 axes (X, Y, and Z), this machine offers flexibility and precision in processing a wide range of materials and parts.

Durability and Reliability: This machine is built to last, with a 1-year warranty on both the machine and its core components, including the motor.

Easy Maintenance and Inspection: The machine comes with a machinery test report and video outgoing-inspection, ensuring transparency and ease of maintenance for the user.

The portable external circle machining machine is a lightweight and effective tool for external circle machining, mainly used for machining external circles, short shafts, chamfers, and bearing journals/seats. This machine is suitable for horizontal and vertical work and can be used for on-site maintenance and turning of internal parts made of steel, copper, stainless steel, and other materials.

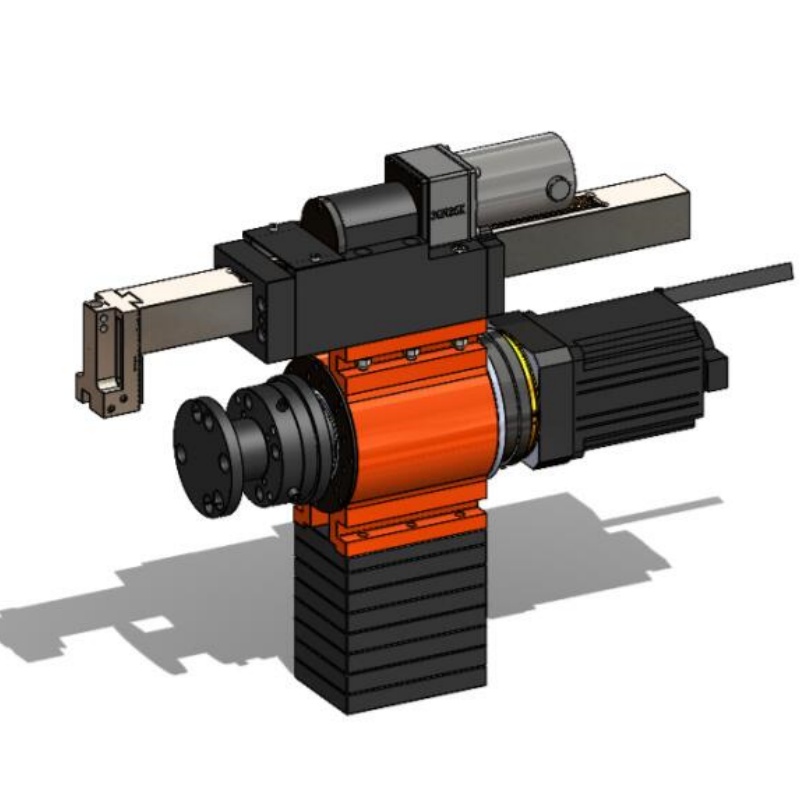

Product Details

External circular processing machine

The outer circle machining machine can achieve micrometer or even sub micrometer dimensional accuracy through high precision, and can obtain excellent surface smoothness, reducing the need for subsequent polishing. It is particularly skilled in processing hard materials such as quenched steel and hard alloys that are difficult to handle by traditional turning. Its precision correction ability can accurately correct the deformation of the workpiece after heat treatment to meet the final accuracy requirements. It has a stable and reliable rigid structure, precision guide rail and spindle system, ensuring a stable machining process, high repeatability, strong universality, and can machine various outer cylindrical surfaces, conical surfaces, end faces, step shafts, crankshaft necks. It is easy to integrate modern machine models with automatic loading and unloading, measurement compensation systems, and achieves efficient automated production.

Model | JS-WY-80 |

Processing range | 80-230mm |

Processing length | 300mm |

Machine speed | 0-150 rpm |

Motor power | 1.8KW |

Feed speed | Stepless speed regulation |

Drive selection | Servo motor |

Fineness | R3.2 |

Ellipticity | 0.02mm |

Taper | 200/0.03mm |

Maximum machining capacity | 1.5mm |

Function | Cylindrical turning,cylindrical welding |

Machine pictures

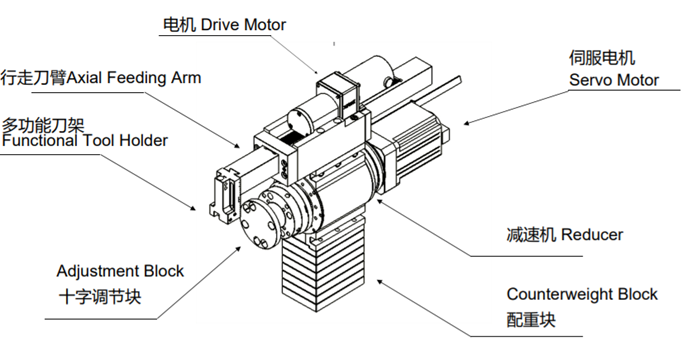

MACHINE LIST

Host | Main control box | ||

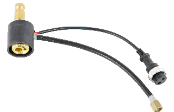

Soldering wire | Split screen control box | ||

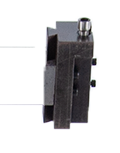

Welding drive motor | Adjustable knife holder | ||

Universal adjustment block | dial indicator | ||

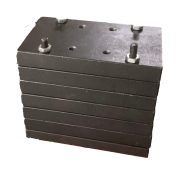

clump weight | Adapter | ||

calipers | Protect the mouth | ||

Conductive nozzle |

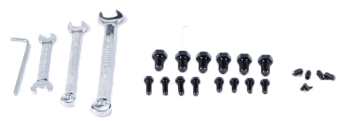

| tool kit | |

cutter bar | Knife grain | ||

SERVICE

Pre-sale services

Provide the free consultation of the equipment

Provide the standard device and the flow chart

According to the clients' special reguirement, offering the reasonable plan and free design helping toselect the equipment.

Services during the sales

1. 24 hours on line service, support Chinese, English, Spanish, French, German, Russian ,technical guidance.

2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.

3. Povide machine install video.

4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.

5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.