Welding Machine

*It has the advantages of high processing accuracy, high precision and good wear resistance, and is suitable for the processing and repair of various complex workpieces.

* The design is reasonable and easy to operate.Operators without professional skills can also master it, reducing labor costs.

Description

In the daily maintenance and repair of construction machinery, there are often such problems: the key parts of the equipment, such as shaft pin holes and hinge holes, suffer from wear and deformation due to long-term use and require urgent repair. However, traditional large-scale boring and welding equipment is bulky and inconvenient to move, making it difficult to operate on-site. At this time, the portable line boring machine comes into play. It can be regarded as the "rain of timely help" for the maintenance of construction machinery. With its small and flexible body, it brings new opportunities to complex maintenance work.

Parameter

| Item | Specification |

| Main Motor Power | 1.8 kW, stepless speed control (0–180 RPM) |

| Feed Box | Stepless speed regulation, automatic feed |

| Feed Motor | 220V, 120W, stepless speed control |

| Boring Diameter Range | Ø80 mm – Ø180 mm |

| Boring Bar Specification | 40 mm × 1500 mm (customizable upon request) |

| Boring Bar Material | 45# steel |

| Boring Bar Processing | Tempered, turned, quenched, ground, surface hard chrome plated |

| Feed Guide Rail | Double cylindrical guide rails (45# steel, tempered, turned, quenched, ground, hard chrome plated) |

| Minimum Cutting Feed | 0.10 mm/rev |

| Maximum Cutting Depth | 2 mm (per side) |

| Working Stroke | 300 mm (customizable upon request) |

| Weight | Approx. 60 kg |

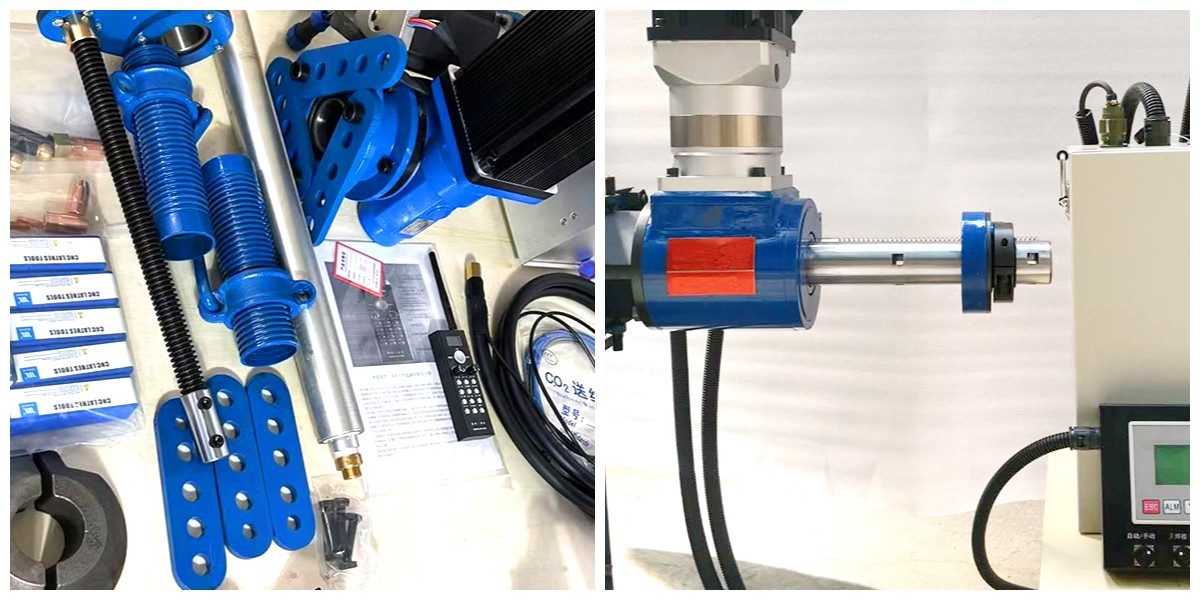

Machine display

For maintenance personnel of construction machinery, the ease of equipment operation directly affects work efficiency. The portable drilling and welding integrated machine performs exceptionally well in this regard. Its operation interface is simple and clear, and it usually comes with an intuitive display screen. Operators only need to follow the prompts on the display screen and input relevant parameters, such as the diameter and depth of the drilling, feed speed, as well as welding current and voltage. The equipment can then operate precisely. Generally, after receiving 1-2 days of training, novice workers can independently complete simple drilling and welding tasks, significantly shortening the training period for operators and making maintenance work more efficient.