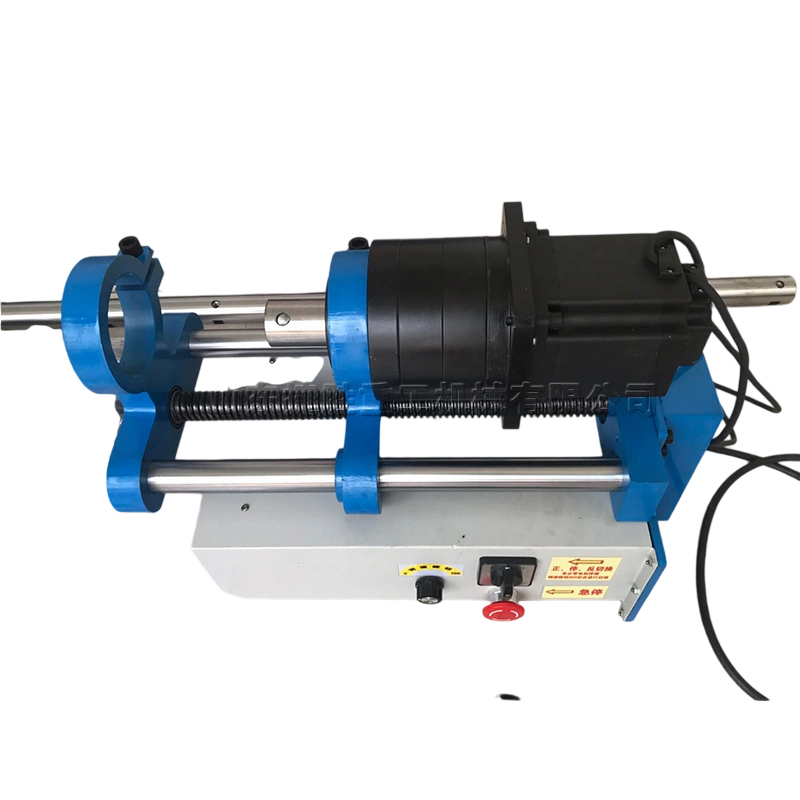

Portable Line Boring Equipment

Versatile Application: Designed for a wide range of construction machinery, such as excavators, loaders, presses, and cranes. Ideal for post-welding hole machining, bushing after reaming, and precision repair of concentric holes.

Easy Installation & Portability: Uses a combination of welded and bolted clamping, making it quick to install and dismantle. Compact structure ensures convenient transport and is perfect for on-site repairs.

High-Precision Cutting System: The boring bar and guide rails are made from 45# steel and undergo tempering, quenching, grinding, and hard chrome plating to ensure excellent wear resistance and cutting accuracy.

Stepless Speed Control: Both the main motor and feed system feature stepless speed adjustment, allowing fine-tuned control of cutting speed and feed rate for different materials and hole sizes.

Strong Customization Capability: The boring bar length and working stroke can be customized to meet special engineering requirements, making it suitable for complex on-site operations.

Overview

The engineering boring machine is used for post-welding machining of pin holes, rotary holes, and articulation holes on various construction machinery structures. It is also suitable for bushing after hole expansion and for the repair and machining of concentric holes on excavators, loaders, presses, cranes, and other machinery.

The 40-type boring machine uses a welding and bolt connection clamping method for installation, making disassembly and transport convenient. It is suitable for machining various concentric holes and multiple adjacent holes. The operation involves continuous cutting.

Technical Specifications

Item | Specification |

Main Motor Power | 1.8 kW, stepless speed control (0–180 RPM) |

Feed Box | Stepless speed regulation, automatic feed |

Feed Motor | 220V, 120W, stepless speed control |

Boring Diameter Range | Ø80 mm – Ø180 mm |

Boring Bar Specification | 40 mm × 1500 mm (customizable upon request) |

Boring Bar Material | 45# steel |

Boring Bar Processing | Tempered, turned, quenched, ground, surface hard chrome plated |

Feed Guide Rail | Double cylindrical guide rails (45# steel, tempered, turned, quenched, ground, hard chrome plated) |

Minimum Cutting Feed | 0.10 mm/rev |

Maximum Cutting Depth | 2 mm (per side) |

Working Stroke | 300 mm (customizable upon request) |

Weight | Approx. 60 kg |

Machine Photos

Packing & Shipping Process