Line Boring Machine And Welding

Multifunction Integration: Combines CNC boring and welding with auto modes for high-efficiency operation.

Portable & Compact: Lightweight design suitable for confined spaces and field servicing.

Digital Precision Control: Advanced digital interface supports automated and manual operations.

Customizable Boring Range: Wide machining range from Φ50 mm to Φ300 mm with adjustable boring bar.

Reliable After-Sales Support: One-year warranty and clear service terms ensure peace of mind.

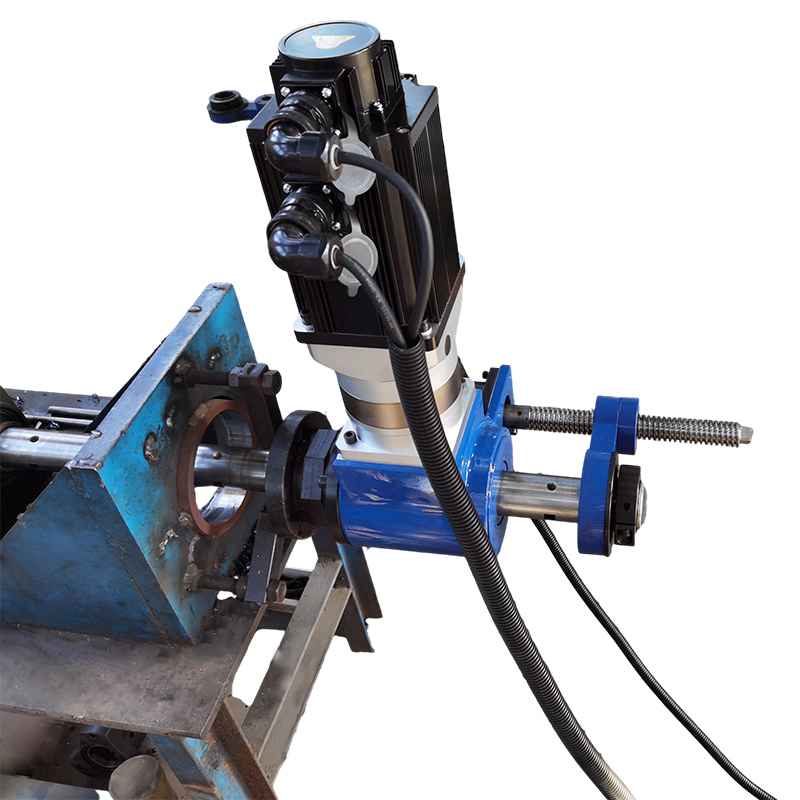

The Line Boring Machine and Welding system features a compact, lightweight design that delivers reliable boring and welding capabilities. Requiring minimal workspace and easy to transport, it's ideal for on-site repairs across diverse industrial settings. Commonly used for restoring pin and bearing holes on heavy-duty machinery, it is a valuable tool for mining, construction, and equipment maintenance sectors.

Product Features

Integrated with an advanced digital control interface, this machine ensures accurate and user-friendly operation. It supports a variety of functions such as standard boring, constant-depth boring, spiral welding, and swing welding. The constant-depth stop function allows for unattended operation, enhancing safety and improving productivity.

Technical Specifications

| Item | Specification |

Boring Diameter Range | Φ50–300 mm |

Boring Stroke | 260 mm |

Boring Bar Size | 50 × 1600 mm |

Power Supply | AC 220V, 50Hz |

Max Power Output | 2.5 kW (stepless speed control) |

Spindl Speed | 0.1–200 r/min |

Welding Diameter Range | Φ55–250 mm |

Recommended Wire Diameter | Φ1.0 mm |

Total Machine Weight | 120 kg |

Environmental Conditions

Operating Temperature: -10°C to +40°C

Storage Temperature: -25°C to +55°C

Relative Humidity: ≤85% at 20°C, ≤50% at 40°C

Storage Requirements: Store in a dry, ventilated area away from direct sunlight and rain.

For long-term storage, apply lubricant to the lead screw and guide rails.

Note:

Fixed-length boring, spiral welding, and oscillating welding are all automatic modes. If none of these modes is selected, the machine defaults to manual mode.

Contract repair:

1. Full machine warranty is valid for one year from the purchase date. Free repair service is provided under proper usage conditions.

2. Warranty does not include replaceable parts such as cables, contact tips, or other consumables.

3. Free maintenance is not applicable in the following cases:

Expired warranty

Damage due to incorrect installation or misuse against operational guidelines

Issues caused by human error, improper storage, unauthorized repair or modifications, or external incidents (impact, fire, natural disaster, etc.)