Metal shaft Journal Lathe

Ultra-High Precision: Achieves micron to sub-micron accuracy with excellent surface finish

Material Versatility: Efficiently processes hardened steels and alloys

Deformation Correction: Compensates heat treatment deformation for final precision

Stable & Universal: Rigid structure supports consistent results across diverse parts

Automation Ready: Easily integrates with modern automated production systems

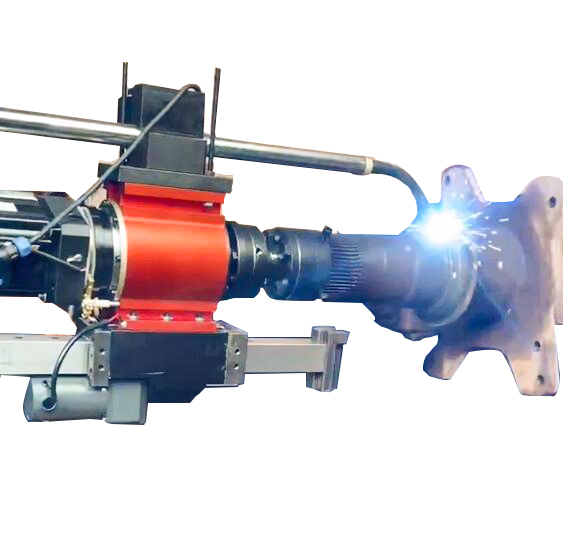

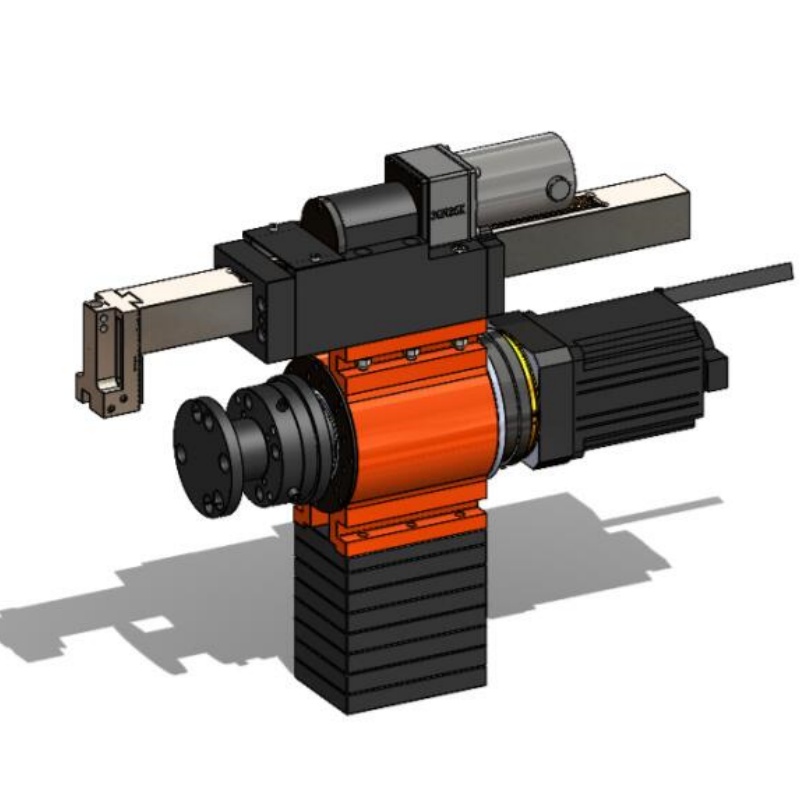

TheMetal shaft Journal Lathe is a compact and efficient solution for external circle processing. It is primarily designed for working on outer diameters, short shafts, chamfers, and bearing journals/seats. Suitable for both horizontal and vertical applications, it enables on-site repair and machining of internal components made from materials like steel, copper, and stainless steel.

Product Details

Metal shaft Journal Lathe

This machine delivers micron-level or even sub-micron precision, achieving superior surface finishes and minimizing the need for post-polishing. It excels in machining hardened materials such as quenched steel and carbide, which are difficult for conventional turning methods. The machine also offers excellent correction ability, accurately adjusting post-heat treatment deformations to meet final precision demands. With a rigid, stable design, precision guides and spindles, it ensures consistent machining quality, high repeatability, and strong versatility. It is capable of processing various shapes including outer cylinders, cones, end faces, stepped shafts, and crankshaft journals. Easily integrated into modern automated systems, it supports automated loading/unloading, real-time measurement, and compensation for efficient mass production.

Model | JS-WY-80 |

Processing range | 80-230mm |

Processing length | 300mm |

Machine speed | 0-150 rpm |

Motor power | 1.8KW |

Feed speed | Stepless speed regulation |

Drive selection | Servo motor |

Fineness | R3.2 |

Ellipticity | 0.02mm |

Taper | 200/0.03mm |

Maximum machining capacity | 1.5mm |

Function | Cylindrical turning,cylindrical welding |

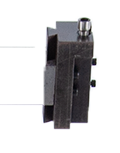

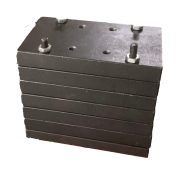

Machine pictures

MACHINE LIST

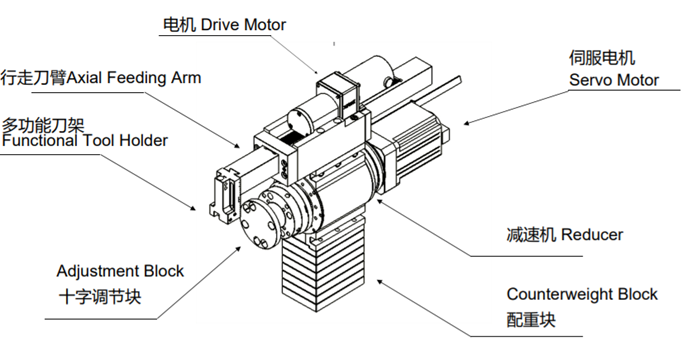

Host | Main control box | ||

Soldering wire | Split screen control box | ||

Welding drive motor | Adjustable knife holder | ||

Universal adjustment block | dial indicator | ||

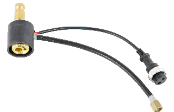

clump weight | Adapter | ||

calipers | Protect the mouth | ||

Conductive nozzle |

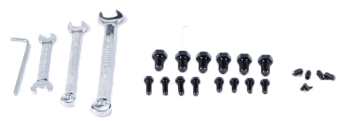

| tool kit | |

cutter bar | Knife grain | ||

SERVICE

Pre-sale Services

Free equipment consultation

Provide standard machines and process flows

Custom plans and free designs tailored to client needs

Services During Sales

24/7 online support in Chinese, English, Spanish, French, German, and Russian

Quick response within 1 hour for machine faults

Machine installation video provided

Shipping support with real-time logistics tracking (DHL, FedEx, etc.)

Non-human machine failure? Replacement machine or parts provided