Mobile boring machine

No-Dismantle Operation: No need to remove arms/cabs, saving time and effort

Dual Repair Modes: Supports welding repair + boring & bushing, adaptable to multiple scenarios

On-Site Repair: Portable design enables on-site restoration directly at the construction site

Overview

The new line bore welder is equipped with an upgraded motor, featuring dual-speed gear adjustment + stepless speed control for flexible operation across multiple working conditions. Its innovative automatic feeding design delivers double the torque of the previous model, ensuring more powerful and stable power output. This portable mobile boring machine requires no complex debugging, efficiently handling various boring and repair tasks. As a reliable portable line boring bar, it provides a more convenient and efficient solution for on-site construction site operations.

Product Advantages

Cab-Free Dismantling: Bores and repairs boom bases without removal, saving time and boosting efficiency

Telescopic Bracket Design: Adapts to diverse working scenarios with flexible and easy installation

Lightweight Components: Effortless transportation and on-site operation, reducing work intensity

Application Scenarios

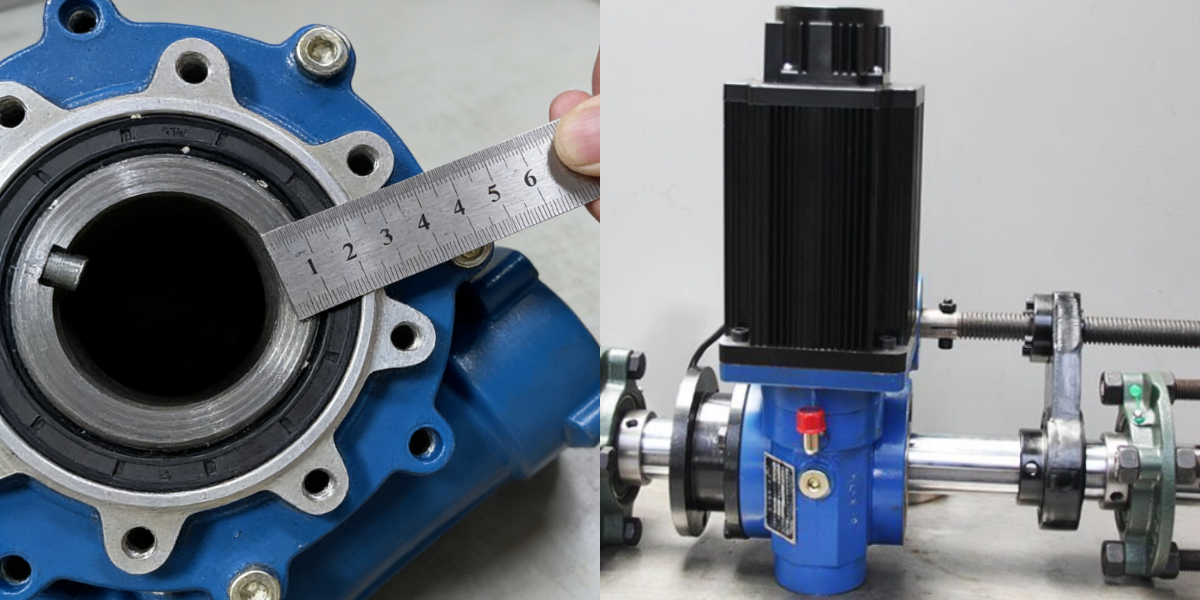

On-site boring repair at the construction site is successfully completed! The boring machine precisely controls the hole dimensions, resulting in smooth, burr-free hole walls that meet equipment assembly standards. No secondary grinding is needed—components can be directly installed, facilitating rapid project resumption and efficiently solving various hole repair challenges.

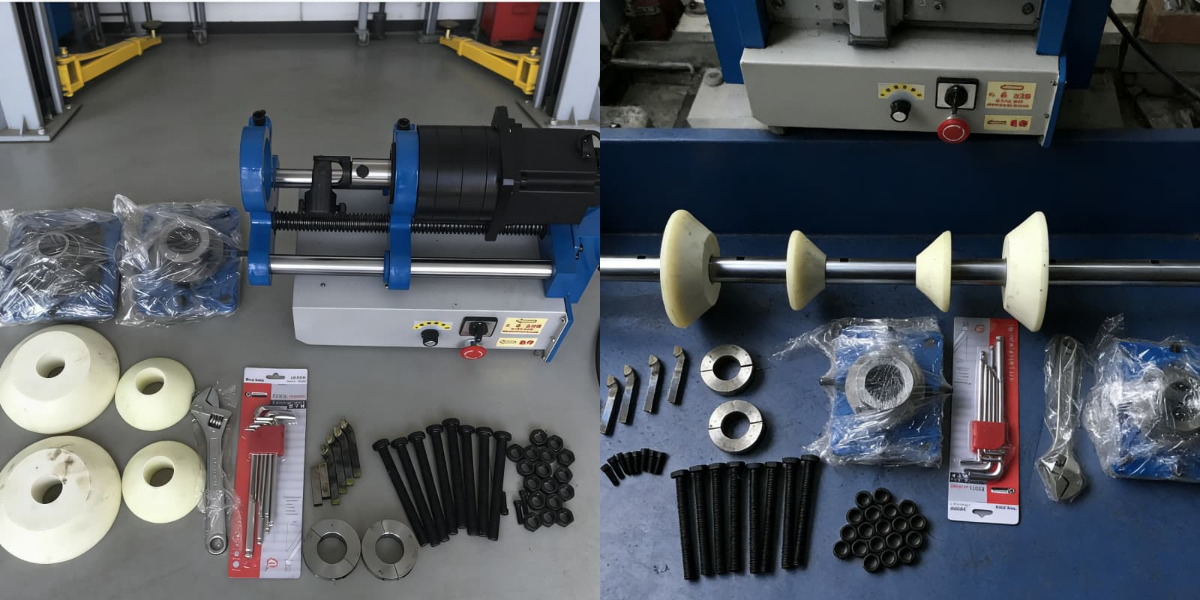

Packaging and Delivery

Live Scene: Portable Boring Machine Shipment!All components are lightweight and easy to carry, with ultra-low operation threshold—no professional experience required. Simply follow the manual to get started quickly. Each unit undergoes strict quality inspection, fully assembled and ready for delivery to customers, empowering efficient on-site boring and repair work at construction sites!

Company Strength Exhibition

We specialize in the foreign trade supply of boring machines, focusing on dual upgrades of materials and craftsmanship—we select high-grade quality steel paired with precision steel casting and quenching-tempering technology to enhance equipment durability and stability, with strict quality control running through the entire production process; leveraging solid manufacturing strength, we provide reliable foreign trade sources for global customers and demonstrate professional supply capabilities.

Customer Cases

Overseas clients visited our factory for on-site inspection, focusing on the steel casting and quenching-tempering process of the boring machines. The equipment features sufficient body strength, wear resistance and durability. After on-site observation and testing, the clients recognized the stable performance and service life of the equipment, and confirmed the purchase order on the spot, demonstrating the product's quality strength.

After-sales Service

We provide a one-year warranty for all sold boring machines, covering quality issues of core components. Within the warranty period, our professional after-sales team responds promptly to global customers' needs, offering technical guidance, troubleshooting support, and spare parts replacement services. Backed by a comprehensive cross-border after-sales system, we break geographical barriers to ensure a worry-free procurement experience for you, with reliable and hassle-free foreign trade supporting services throughout the entire process!

FAQ

1. What speed control modes does the new line bore welder support, and how does it adapt to different working conditions?

The new line bore welder is equipped with an upgraded motor, featuring dual-speed gear adjustment plus stepless speed control. This dual-mode speed regulation enables flexible operation across multiple working conditions, meeting the diverse speed requirements of different boring and repair tasks.

2. How does the innovative automatic feeding design of the machine improve work efficiency?

The machine’s automatic feeding design delivers double the torque of the previous model, ensuring more powerful and stable power output. This enhanced torque allows for more efficient handling of various boring and repair tasks, while eliminating the need for manual feeding operations that are time-consuming and labor-intensive.

3. Does the portable boring bar require complex debugging before use?

No, this portable boring bar does not need complex debugging. It has an ultra-low operation threshold—even users without professional experience can quickly get started by simply following the operation manual, which helps save on-site preparation time and improve work efficiency.