Line boring and welding machine

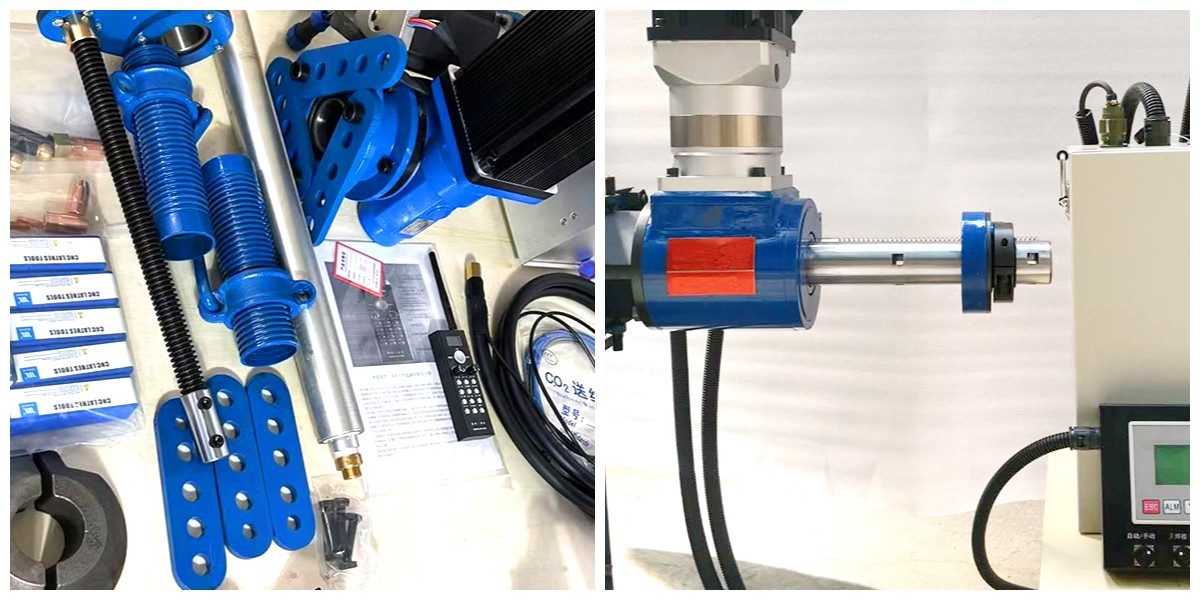

Pure copper motor

It operates smoothly. With an all-copper motor, it has a long service life. The vertical structure allows for boring and welding even in narrow spaces.

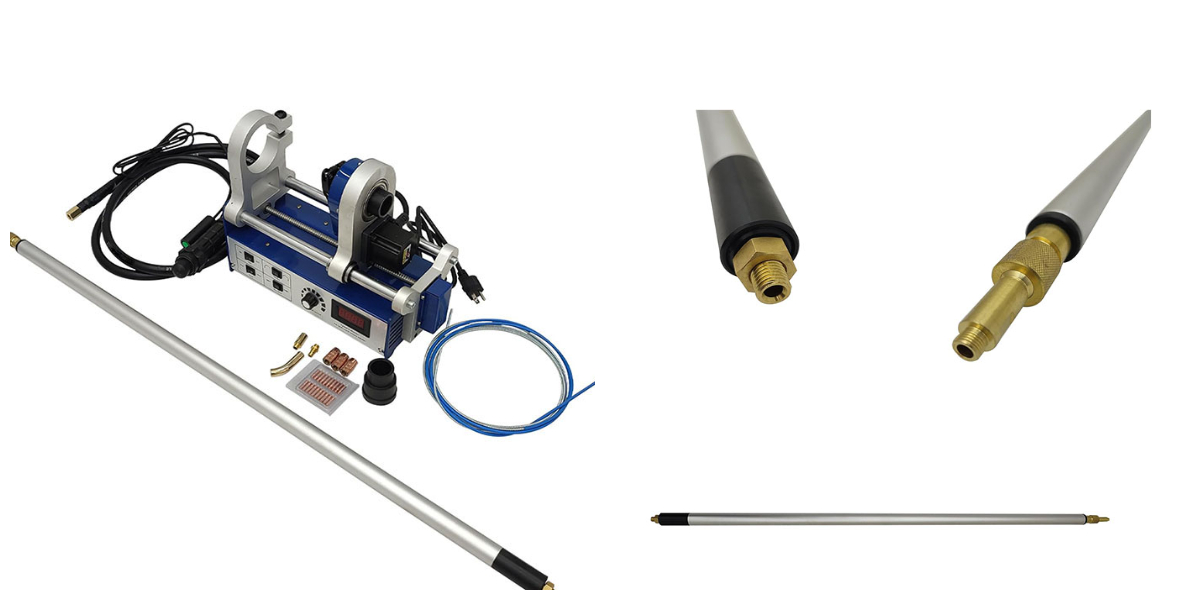

Boring bars and welding rods

There are two boring bars and two welding rods in total, one long and one short. They can be used in combination for special positions, enabling boring and welding for the entire vehicle.

Handle control

It has high durability, is not easily damaged by bumps, and is highly practical, supporting both manual and automatic operation.

Description

This boring and welding machine features a pure copper motor as the core, with strong power, low energy consumption, smooth and noiseless operation, and a lifespan far longer than ordinary motors. Its vertical structure is flexible, easily handling boring, hole repairing and welding in narrow areas. It has two long and short boring bars and welding rods, made of durable and wear-resistant material, which can precisely fit special positions for full-vehicle boring and welding. It also comes with complete accessories to meet various operation needs, and the handle is durable and impact-resistant, enabling convenient and efficient manual-automatic integrated operation.

Parameter

Item | Specification |

Main Motor Power | 1.8 kW, stepless speed control (0–180 RPM) |

Feed Box | Stepless speed regulation, automatic feed |

Feed Motor | 220V, 120W, stepless speed control |

Boring Diameter Range | Ø80 mm – Ø180 mm |

Boring Bar Specification | 40 mm × 1500 mm (customizable upon request) |

Boring Bar Material | 45# steel |

Boring Bar Processing | Tempered, turned, quenched, ground, surface hard chrome plated |

Feed Guide Rail | Double cylindrical guide rails (45# steel, tempered, turned, quenched, ground, hard chrome plated) |

Minimum Cutting Feed | 0.10 mm/rev |

Maximum Cutting Depth | 2 mm (per side) |

Working Stroke | 300 mm (customizable upon request) |

Weight | Approx. 60 kg |

Factory Introduction

Multiple models available, custom services supported, meeting needs of different working scenarios

Quality guaranteed, operation with integrity, manufactured using high-quality materials to ensure stable and durable equipment

Direct warranty from the manufacturer, considerate after-sales service, reliable product quality and complete after-sales system

Direct supply from the manufacturer, eliminating intermediate links, shortening the distance between manufacturer and buyer for higher cost-effectiveness