Boring and welding integrated machine

High-Precision Integrated Processing: Boring accuracy reaches ±0.01mm, and welding seam flatness error is ≤0.5mm—this dual high precision meets strict industrial standards. Equipped with double cylindrical guide rails and a high-rigidity machine body, there’s no wobble during processing, and repeat positioning accuracy stays stable. This ensures precise borehole dimensions, smooth hole walls, and qualified welding joint strength.

Multi-Scenario Processing Adaptability: It covers boring needs for hole diameters from φ20mm to φ500mm, compatible with heavy machinery parts (such as excavator slewing bearing holes, crane main arm connection holes), pressure vessel sections, and steel structure components. For welding, it works with multiple materials like carbon steel, stainless steel, and alloy steel—solving "boring + welding" composite processing needs in one stop.

High Durability & Low Maintenance Costs: Core components (boring spindle, welding head) are forged from high-strength alloy steel, offering strong deformation resistance and a continuous operation lifespan of over 8,000 hours. Key connection parts use a sealed dust-proof design, reducing wear on internal components from dust and debris, and cutting down long-term maintenance frequency and costs.

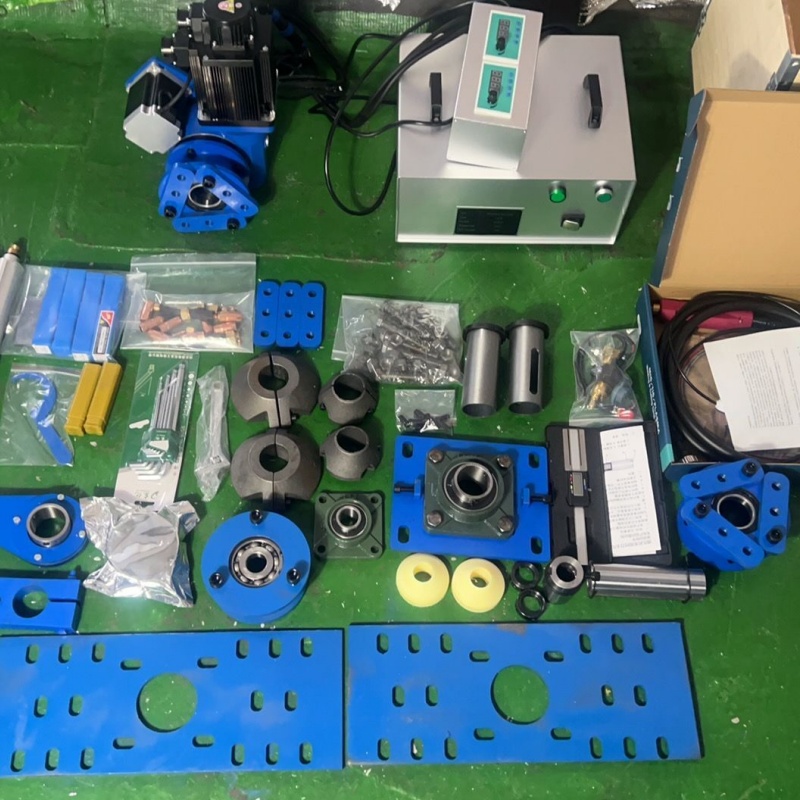

Product Details

The boring-welding integrated machine is a composite processing device designed specifically for industrial manufacturing and equipment maintenance scenarios. No need to split processes or switch equipment—you can finish integrated operations of workpiece boring, welding, and precise positioning in one go.In the construction machinery field,The line boring equipment used for post-welding processing and wear repair of pin holes and lifting ring holes on excavators, loaders, and crawler cranes. In the pressure vessel and steel structure industry, it can complete boring of section connection holes and circumferential seam welding simultaneously. It also adapts to on-site processing of large workpieces like mining equipment parts and heavy truck frames—especially suitable for high-precision processing scenarios requiring multi-hole concentricity (concentricity error ≤0.03mm). One positioning and installation is enough to finish multiple processes, significantly shortening the processing cycle.

Specifications

Product name | |

Motor | 2.6KW |

Voltage | 220V/50HZ |

Boring bar one | 45*1500mm |

Boring bar two | 45*750mm |

Welding rod one | 30*1200mm |

Welding rod two | 30*750mm |

Processing diameter range | 48-260mm |

Welding wire | 0.8-1.2mm |

Bearing housings | One |

Product Details

Easy Installation & Movement: Adopting a modular design, it supports two installation methods—welding fixation and bolt clamping—suitable for both fixed workshop operations and on-site mobile processing. The machine weighs ≤500kg, with detachable lifting rings. 2-3 people can handle transportation and assembly, making it flexible for different working environments.

Efficient Continuous Processing: The boring part uses a stepless speed change spindle, with adjustable cutting speed from 0 to 150r/min. Paired with an automatic feed system, rough boring and fine boring can be done continuously. The welding part is equipped with a digital pulse power supply, supporting two modes: CO₂ gas shielded welding and TIG welding. Arc striking success rate is ≥99%, with no arc break during continuous welding—production efficiency is over 40% higher than traditional separate equipment.

User-Friendly Operation: It comes with a 7-inch touchscreen, pre-installed with over 100 parameter templates for common workpiece processing—beginners can call them up with one click. It supports manual/automatic dual-mode switching; in automatic mode, you can preset the processing flow, and the machine completes the full "positioning - boring - welding - inspection" process independently. This reduces manual intervention and lowers the operation threshold.

Factory Profile

Packaging and Delivery

Service Commitment

Pre-Sales Service

Free consultation: function, price, scenario

Custom plan per area & terrain

Book visit to check production & QC

In-Sales Service

Full inspection: multi-test before delivery

1-on-1 guidance: install & operate

24h response to in-sales issues

After-Sales Service

1-year warranty: free fault repair

Lifelong support for tech problems