Portable line boring equipment

Multi-Process Function Compatibility: It works with a range of functional components, including CNC boring heads, automatic welding arms, and precision positioning fixtures. This covers the "one-machine, two-functions" needs—like boring metal workpieces, welding seams, and subsequent precision positioning and fixing. You can finish multiple core processes without swapping out equipment frequently.

Fast Process Switching: It comes with an intelligent linked switching system, so no manual disassembly of complex components is needed. Switching from a CNC boring head to an automatic welding arm takes just 4-6 minutes. This slashes the gap between processes, cuts down on equipment downtime, and boosts overall processing efficiency.

Customized Process Support: We match dedicated functional components to the user’s specific processing scenario. For example, large-diameter boring heads for heavy machinery or high-temperature-resistant welding arms for pressure vessels. This ensures a precise fit for different workpieces’ processing needs, enhancing process targeting and machining accuracy.

Product Introduction

The boring-welding integrated machine is a high-efficiency, high-precision metal processing device, built specifically for composite processing needs in the industrial manufacturing field. It uses a CNC programming control system, paired with a human-machine interactive touch panel and automatic positioning calibration. The operation logic is clear and straightforward—even operators new to the machine can master core operations quickly after a short training.What’s more, the machine has a high-rigidity body and high-precision guide rail structure. Combined with the CNC boring head’s micron-level feed accuracy and the welding arm’s angle adaptive adjustment, it performs well in scenarios like heavy machinery part processing and pressure vessel manufacturing. It can handle both high-difficulty boring and high-quality welding, making it a core device for improving processing efficiency and precision in industrial manufacturing.

Specifications

Name | |

Scope boring | 55-300 mm |

Boring working stroke | 260mm |

Boring bar specification | 50*1600mm |

Working voltage | 220V |

Maximum power | 2.5KW |

Spindle speed | 0.1-200r/min |

Welding scope | 55-250 mm |

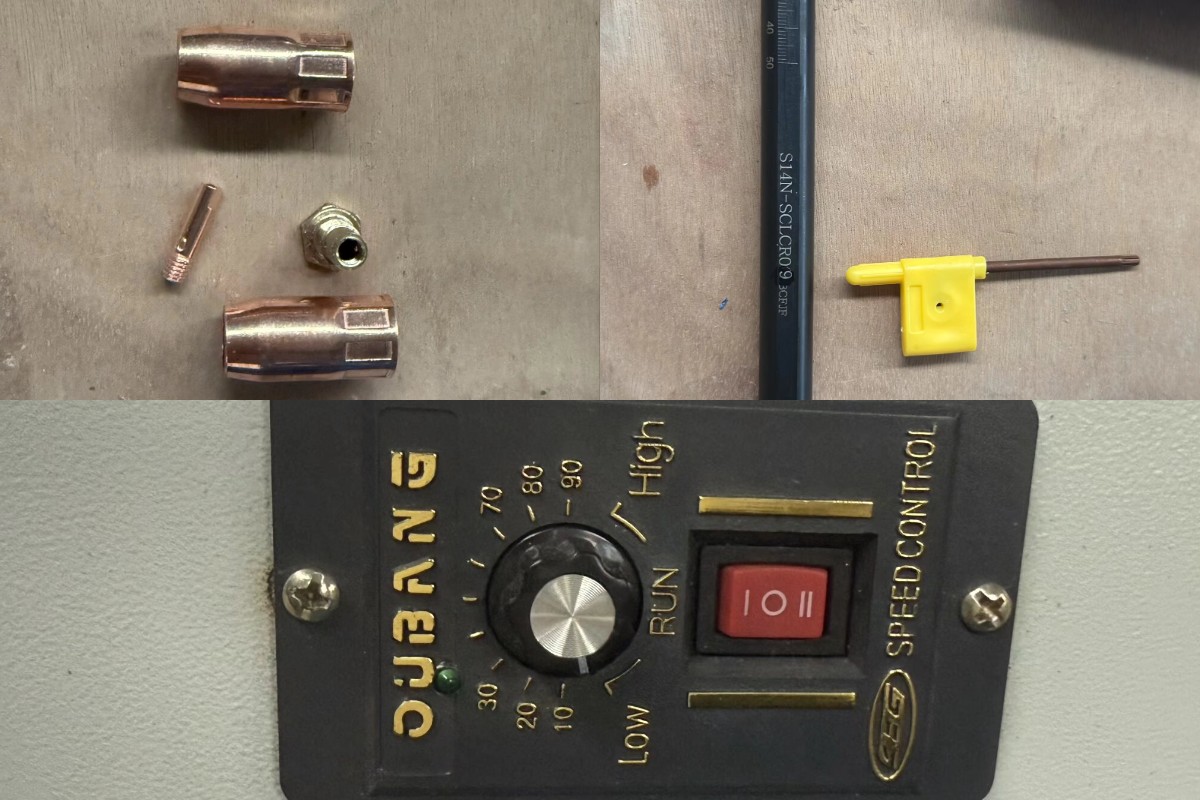

Wire diameter | 1 |

Machine weight | 50KG |

Product Details

Key Features:

Cross-Scenario Processing Adaptability: It fits multiple scenarios—boring and welding heavy machinery parts, processing pressure vessel section connections, precision welding of steel structure components, and repairing mining equipment accessories. No need to replace the main machine body; just adjust the functional components to meet different processing requirements.

Functional Component Collaboration: Some functional components can work together. Take precision positioning fixtures paired with CNC boring heads and automatic welding arms, for example. First, use the fixture to fix the workpiece and set the reference position. Then the boring head does high-precision boring. Finally, the welding arm performs seal welding on the workpiece joints. This creates an integrated "positioning-boring-welding" process flow, greatly improving processing continuity and finished product precision.

Secure and Reliable Component Connection: The interface between functional components and the main machine uses a standardized quick-install structure, reinforced with high-strength locking buckles and a dust-sealing design. This keeps components firmly connected during high-speed boring or high-temperature welding—no risk of displacement or loosening. It ensures stable processing and avoids machining errors or equipment damage caused by loose components.

Precise Matching of Component Performance: The machine’s CNC system links with the hydraulic drive module, adjusting parameters precisely based on the processing needs of different functional components. For instance, it controls the CNC boring head’s feed speed (low speed for high-precision boring, high speed for rough processing) and fine-tunes the welding arm’s current intensity and welding speed (low current for thin parts, high current for thick part penetration welding). This brings out the best performance of each component.

Expandable Accessory Compatibility: The machine has 2 reserved standardized expansion interfaces. Later, if new processing needs arise, you can add compatible accessories—like laser detection probes or automatic wire feeding devices. No major modifications to the main machine structure are needed, which reduces upgrade costs, extends the machine’s service life, expands its applicable processing scenarios, and increases its long-term value.

Factory Profile

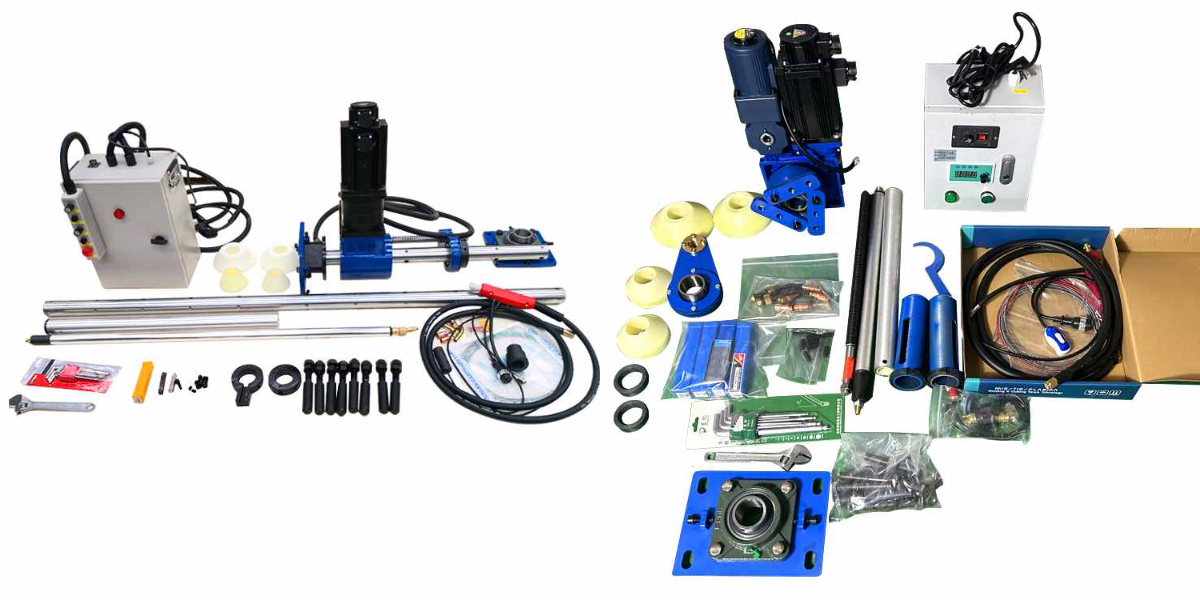

Packaging and Delivery

Service Commitment

Pre-Sales Service

Free consultation: function, price, scenario

Custom plan per area & terrain

Book visit to check production & QC

In-Sales Service

Full inspection: multi-test before delivery

1-on-1 guidance: install & operate

24h response to in-sales issues

After-Sales Service

1-year warranty: free fault repair

Lifelong support for tech problems