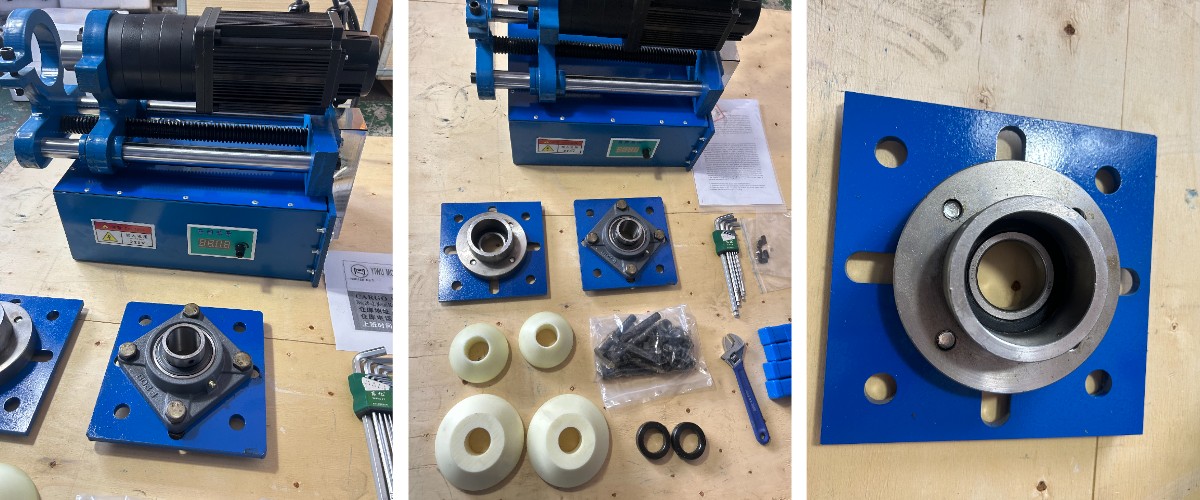

Portable Line Boring Machine

Wide Application: Suitable for repairing shaft pin holes, hinge holes, and concentric holes on various heavy machinery.

Stable & Accurate: Alloy boring bar with heat treatment ensures high precision, hardness, and wear resistance.

Stepless Speed Control: Both feed and spindle support stepless adjustment for flexible cutting.

Easy On-Site Installation: Modular design with weldable supports enables quick setup and disassembly.

Expandable Functions: Supports optional facing and end-boring based on user requirements.

The boring machine of construction machinery is used for repairing welding of shaft pin hole, turning hole, hinge hole or insert sleeve after reaming on various construction machinery structure.Repair and processing of equivalent core hole of excavator, loader, press, crane.

The boring machine is installed by welding machine and bolt fixed clamp, which is convenient for disassembly and transportation. Latt-40 boring machine is suitable for many kinds of concentric hole, side by side porous processing. The work is continuous cutting, high production efficiency, high machining accuracy.

Our company is committed to the field processing equipment research and development and manufacturing who can be customized according to the specific needs of customers for various USES of on-site processing equipment, and continue to carry out product technology research and development and innovation. Product structure, working principle and other aspects are continuously improved. Therefore, the product object may be slightly different from the description structure. Please pay attention to it when using. We will provide customers with the latest technical information in the shortest time, so that customers can get the ideal use effect.

Operating instruction

Read the instructions carefully before use and check whether the items are safe according to the packing list. If the number of items does not conform to the packing list, it should be put forward and contacted with our company in time. If the product has been used, our company will not be responsible for it.

(1) The equipment operators should receive safety operation training.

(2) The operator must wear overalls, insulating shoes and protective glasses.

(3) Check the voltage on the nameplate before starting, and check whether the on-site power supply is consistent with the power supply.

(4) Check whether the clamping system is locked before starting

(5) to find the correct work only must be put in neutral with the hand to pull or open the lowest gear to find the correct, not allowed to drive high speed to find the correct.

(6) After the equipment is started, please do not put your hands or other objects near the equipment to avoid personal injury.

(7) The wire should be protected from high temperature, grease, sharp edges and other places.

(8) When the sound is abnormal or malfunction occurs, the power should be immediately turned off, and then check and repair.

(9) the operation of the equipment shall be taken care of by special personnel. It is strictly forbidden to operate the equipment by itself.

(10)It is strictly forbidden to use beyond or below the indicated processing scope, and our company will not be responsible for the consequences.

(11) The maximum cutting capacity of the equipment should not be exceeded. No matter the boring bar or the direction of feeding, the direction can only be switched until the motor stops completely. Otherwise, our company will not assume the responsibility for the failure of the motor.

(12) It is strictly prohibited to change the direction of feed after operation.

(13) After the completion of the work, the oil stains on the equipment should be removed in a timely manner, and the anti-embroidery oil should be daub on the metal cutting in a timely manner.

(14) According to the maintenance requirements, do the maintenance and maintenance of the equipment.

Equipment performance characteristics

(1) mainly used for shaft pin hole, rotary hole, hinge hole after welding processing, or after reaming insert sleeve: excavator, loader, crane equivalent coaxiality of the core hole.

(2) the spindle and cutting tool of the boring machine adopt 220v motor, which has the characteristics of low speed and large torsion gauge. The whole machine can achieve smooth cutting and excellent performance.

(3) Axial movement and no vibration in cutting performance.

(4) Feed and spindle stepless speed adjustment.

(5) Boring bar adopts alloy structure. After processing and heat treatment, it has the characteristics of high precision, high hardness, anti-fatigue and wear-resisting.

(6) The tool holder can be fixed in any position within the range of effective travel.

(7) Motor controller is equipped with dynamic delay brake device to avoid vibration when stopping.

(8) The equipment also has the boring end face expansion function, the customer may choose according to the processing needs.

Parameters of the technology

| Item | Specification |

Minimum Machining Diameter | 45 mm |

Maximum Machining Diameter | 160 mm |

Maximum Stroke | 300 mm (customizable) |

Max Cutting Depth (Single Side) | 2 mm |

Surface Roughness | Ra ≤ 3.2 |

Hole Roundness Error | ≤ 0.02 mm |

Spindle Speed | 0 – 80 RPM |

Total Equipment Weight | 60 kg |

Maintenance

In order to ensure the normal work of the boring machine, ensure the accuracy, extend its service life and reduce the maintenance cost, the boring machine must be carefully maintained on a regular basis.

(1) the feeding box is composed of gears, and an appropriate amount of grease is added every three months.

(2) when using, it should be gently lifted and put down. The processed surface should not be damaged. Sufficient lubricating oil should be added to the moving parts.

(3) for long-term storage, the boring machine shall be coated with anti-rust oil, and each part shall be wrapped with oilcloth, pay attention to moisture.