Track Pin Chain Press

Field-Ready Design: Lightweight and compact, perfect for outdoor and remote jobsites.

No Power Dependency: Operates without electricity; ideal for emergencies or rural repairs.

Simple Maintenance: Fewer components and oil paths, easy to clean and service.

Cost-Effective Solution: Lower investment while retaining core hydraulic functionality.

User-Friendly Operation: Easy to handle with manual control, suitable for mobile technicians.

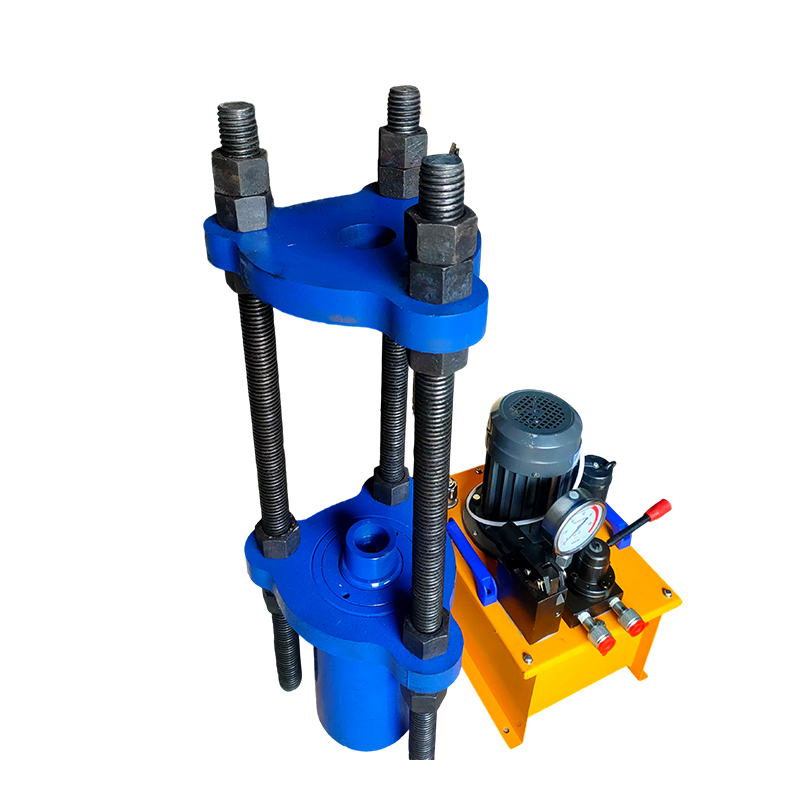

The Track Pin Chain Press is a specialized hydraulic tool designed for removing and installing crawler pins in track-type excavators. Using hydraulic pressure instead of hammering or gas cutting, this equipment ensures precision and protects the track components from damage. It is the ideal solution for on-site excavator undercarriage maintenance.

Driven by a hydraulic electric pump (220V/380V) or a manual hydraulic pump, the system converts hydraulic energy into mechanical force to efficiently disassemble track pins. The portable chain press is engineered for both field and workshop operations, offering convenient mobility, compact design, and high operational safety.

Features

Hydraulic Precision Disassembly: Replaces traditional gas cutting and manual striking methods with high-pressure hydraulic action.

Electric or Manual Options: Available in two versions—electric-powered for high-efficiency and manual for field convenience.

Portable & Lightweight: Designed for use in both repair shops and on-site in remote locations.

Track Protection: Clean removal without damaging the pin or the surrounding track link structure.

Dual-Action Hydraulic System: Simplified two-way oil path ensures smoother movement and easier maintenance.

Specifications

| Parameter | Details |

Power Supply (Electric Model) | 220V / 380V |

Working Pressure | Up to 63 MPa (hydraulic system) |

Oil Type | N46 anti-wear / low-condensation hydraulic oil (filtered) |

Oil Tank Volume | Customizable (requires ≥80% fill for operation) |

Recommended Oil Filter Size | 80–100 mesh |

Control System | Manual or electric reversing valve |

Maximum Allowable Test Pressure | 2.5 MPa (10 minutes) |

System Type | Bi-directional hydraulic system |

Structure Overview

Main Press Body: Heavy-duty steel structure with adjustable mounting brackets for stable pin alignment.

Hydraulic Cylinder: High-pressure cylinder for pushing out and pressing in pin shafts.

Electric Pump Station (Electric Model): Compact unit with digital pressure gauge and motor protection system.

Manual Pump (Manual Model): Hand-operated hydraulic system with two-way valve control for field flexibility.

Reversing Valve & Gauge: Allows directional control and precise pressure monitoring.

Hoses & Connectors: High-pressure rated fittings with safety locking mechanism.

Applications

The Chain Press is widely used in:

Excavator Track Maintenance

Efficient removal and installation of track pins without damage.Heavy Machinery Workshops

Safe and clean disassembly of undercarriage components.Field Repair Services

Portable for on-site breakdown service, including mining, construction, and forestry.OEM and Aftermarket Servicing

Ideal for machine dealers, equipment rebuilders, and service companies.