Why Turkmen companies trust cnc boring and welding machines?

Real Solutions for Turkmenistan’s Pipeline, Gas Field & Factory Work

Turkmenistan’s industrial scene is blowing up—new gas fields, longer pipelines, and bigger factories are popping up left and right.For local companies and the contractors working with them, the biggest headache? Keeping up with tight deadlines and tough conditions without breaking the bank.That’s why everyone’s grabbing bore-weld machines lately.These all-in-one tools aren’t just fancy gear—they’re the reason projects stay on track, save money, and don’t fall apart in the desert. Here’s the real deal on why they’re a must-have for any Turkmenistan project.

1. No More Running Around: Get Boring & Welding Done in One Spot

If you’ve worked on Turkmenistan’s pipelines or gas fields, you know the struggle:parts are heavy, job sites are spread out (some in the middle of nowhere), and moving stuff between separate boring and welding machines is a disaster.Imagine having to take a pipeline joint from a boring shop 100km away to a welding site—you waste a full day, risk damaging the part, and mess up your timeline.

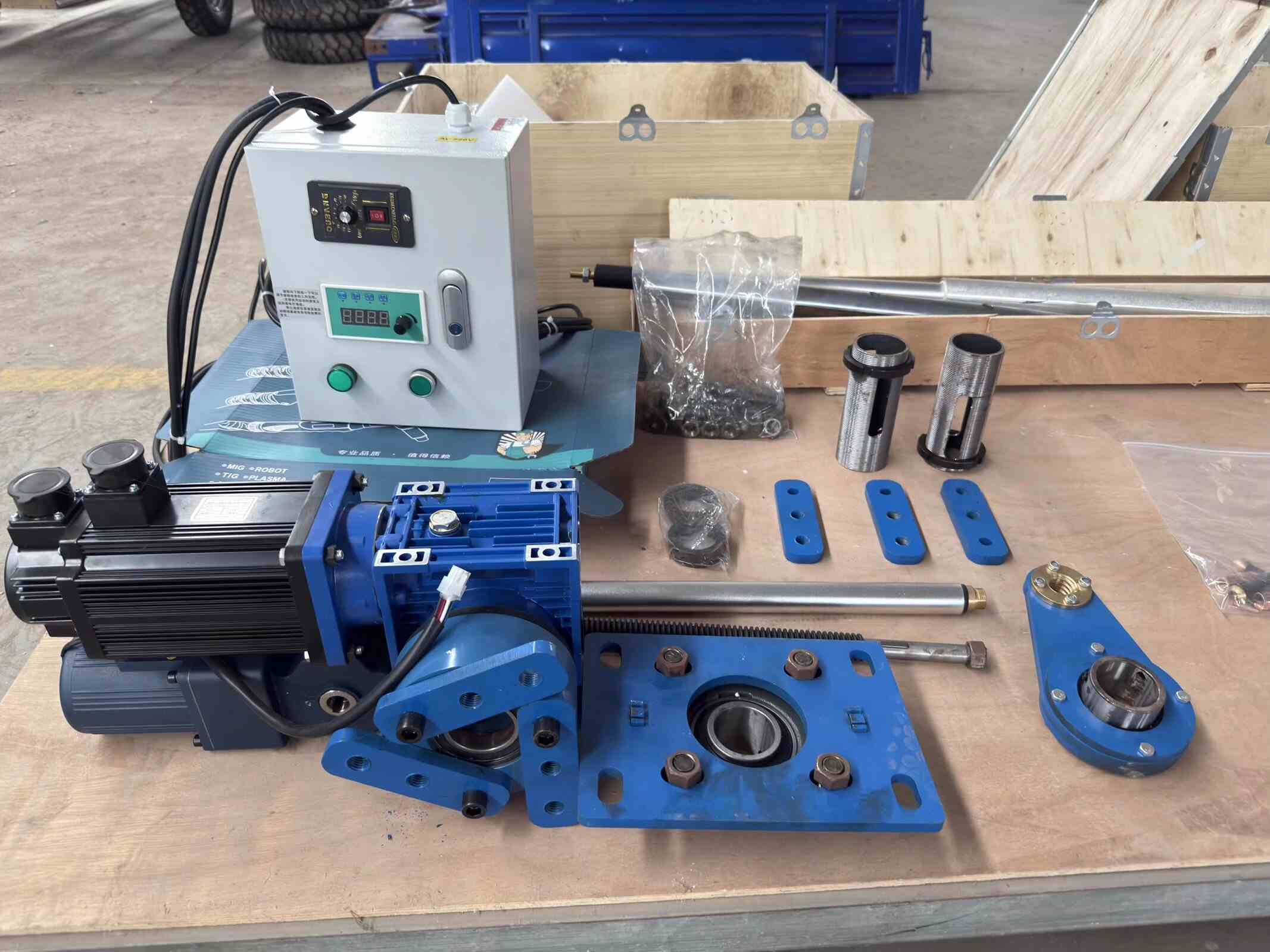

The integrated welding &boring machine fixes this by doing both jobs in one.You bring the machine to the project, not the other way around.Need to fix a leaky pipeline in the Bagtyyarlyk Contract Area? Set up the machine on-site, bore the part to the right size, and weld it up—no transport, no waiting, no mistakes from moving pieces around. For urgent repairs or tight deadlines .this cuts job time in half. It’s not just efficient—it’s the only way to keep up with Turkmenistan’s fast-paced projects.

2. Built to Survive Turkmenistan’s Tough Conditions

Let’s be real: Turkmenistan’s environment is brutal for equipment.Desert heat hits 50°C in summer, dust gets everywhere, and half the job sites are so remote you can’t get a mechanic out quickly. Separate boring or welding tools? They break down, get clogged with dust, or overheat before the job’s done.

The industrial bore-weld machine is built like a tank.It’s got a thick steel frame that keeps dust out and handles vibrations, and it’s compact enough to throw on a truck and haul to even the most isolated gas fields.We’ve seen these machines work for months in the Karakum Desert without a single breakdown—welding thick pipeline joints, boring parts for fertilizer plants,and holding up through sandstorms.Unlike flimsy single-function tools that need constant tweaking,this one just keeps going.For Turkmenistan’s job sites, “tough” isn’t an option—it’s a requirement, and these machines deliver.

3. Saves Money Where It Counts for Growing Businesses

Turkmenistan’s companies aren’t just looking to get jobs done—they’re looking to grow. Buying two separate machines (boring + welding) costs a fortune upfront, and then you’ve got to pay extra workers to operate them, plus maintenance fees when they break. For small to mid-size businesses, that’s a budget killer.

The Automatic 2 In 1 Portable Line Boring And Welding Machine slashes those costs.First, one machine replaces two—so you’re not dropping cash on duplicate gear. Second, it’s super easy to use: local teams pick it up in a day, no fancy training needed, so you don’t have to hire expensive specialists. Third, fewer machines mean fewer repairs—you’re not wasting money on parts or downtime when a tool breaks. We’ve had clients tell us this machine saved them 30% on equipment and labor costs in their first year. For businesses looking to reinvest in bigger projects (like expanding gas field operations), that’s money in the bank.

Why Turkmenistan’s Top Contractors Swear by These Machines

At the end of the day, Turkmenistan’s projects don’t care about fancy specs—they care about getting the job done, on time, on budget, and without hassle. The Intelligent Cnc Boring And Welding Machine checks all those boxes. It eliminates the headache of moving parts, stands up to the desert, and keeps costs low. Whether you’re fixing an old pipeline, building a new factory, or expanding a gas field, this tool isn’t just helpful—it’s essential.

If you’re tired of dealing with slow, fragile equipment that eats into your profits, it’s time to switch. Reach out today to talk about how our bore-weld machine fits your project—we’ll even walk you through how it works for your specific job, whether it’s pipeline repairs or factory fabrication. Let’s keep your Turkmenistan projects moving—no stress, no delays, just results.