Indian client visits factory, orders 30 boring machines

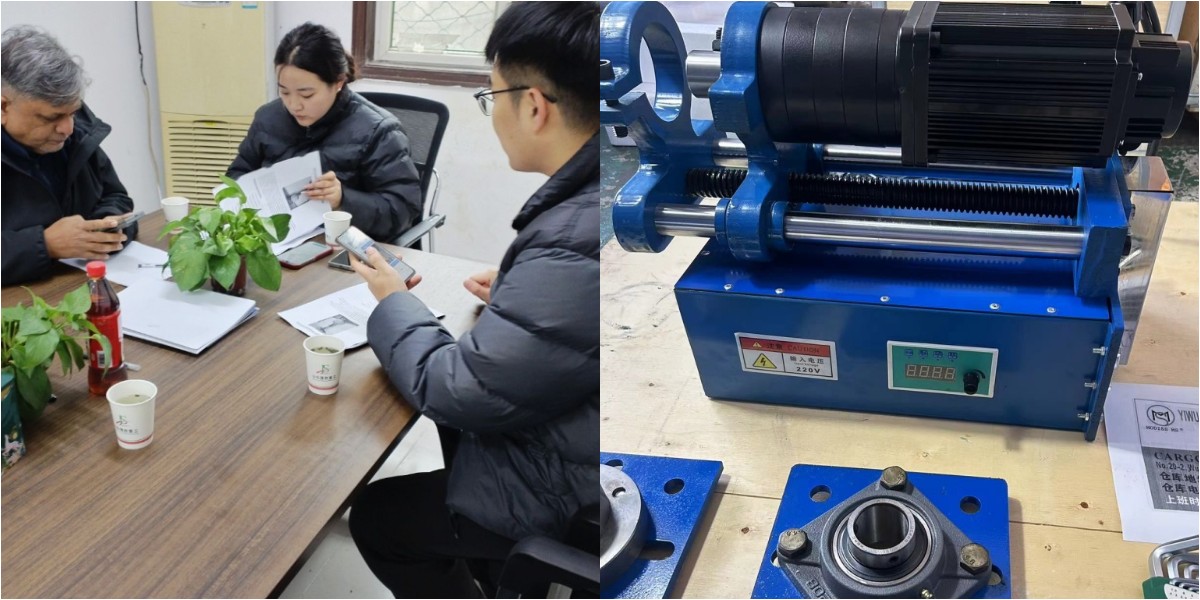

In the world of industrial machinery, trust is earned—not given. That’s why when a leading Indian engineering company specializing in agricultural and construction equipment reached out to us, they didn’t just want a quote—they wanted to see our factory, meet our team, and test our boring machines for themselves.After a 3-day on-site visit, they signed a deal for 30 portable boring machines—marking one of our largest single orders from India. But this wasn’t a last-minute decision: it was the result of transparency, quality, and aligning with the client’s unique needs. Here’s how it happened.

1. The Client’s Needs: Precision, Durability, and Affordability

The Indian client designs and manufactures gearboxes, shafts, and housings for tractors and small construction equipment. They were struggling with their current boring machines: inconsistent precision (leading to rework), frequent breakdowns, and high maintenance costs.They needed a solution that could:

Hold tolerances of ±0.01 mm for gearbox housings (critical for smooth operation)

Withstand 12-hour daily use (their production lines run around the clock)

Stay within their budget (they were expanding and needed 30 machines without overspending)

They’d researched 5 manufacturers before contacting us—what set us apart? We didn’t just send a spec sheet: we invited them to our factory to see exactly how our machines are built.

2. The Factory Visit: Transparency Won Their Trust

We showed them every step of the process—from cutting steel for the frame to assembling the spindle and testing the final product. They watched our workers use CNC boring machines to ensure precision and checked the quality of materials firsthand.Live Testing: We set up a demo with their own gearbox housing part. Our line boring machine completed the job in 8 minutes (their current machines took 12) with a tolerance of ±0.008 mm—better than their requirement. They also tested the machine’s durability by running it continuously for 4 hours—no overheating, no vibrations, no errors.Quality Control Process: They visited our QC lab, where every machine undergoes 24 hours of continuous testing before shipment. We shared our defect rate (less than 0.5%) and showed them our customer feedback from other Indian clients (we supply 120+ machines to India annually).As their production manager put it: “We didn’t just buy machines—we bought peace of mind. Seeing how you build them and testing them with our own parts proved you’re not cutting corners.”

3. The Deal: Customization and Support Sealed It

While quality and precision won their interest, customization and after-sales support sealed the deal. They’re expanding their production to meet growing demand in India’s agricultural sector, and they needed a manufacturer who could grow with them.Final Thought: In B2B Machinery, Trust Is Everything.This order isn’t just a win for us—it’s a reminder that in the industrial world, clients don’t just buy specs—they buy trust.

If you’re in the market for horizontal boring machines (or any industrial equipment), don’t be afraid to ask for a factory visit. The best manufacturers will welcome the chance to show you their work—and that’s how you find partners you can rely on for years to come.