Excavator Track Pin Removal

High Efficiency: Powered by 220V/380V electric pump, allows for rapid pressurization and pin removal.

Hands-Free Precision: Controlled pressing force avoids pin deformation and protects the track.

Digital Pressure Monitoring: Accurate real-time monitoring via built-in pressure gauge.

Ideal for Workshops: Suited for regular, high-frequency maintenance operations.

Consistent Performance: Electric operation ensures stable output and reduces user fatigue.

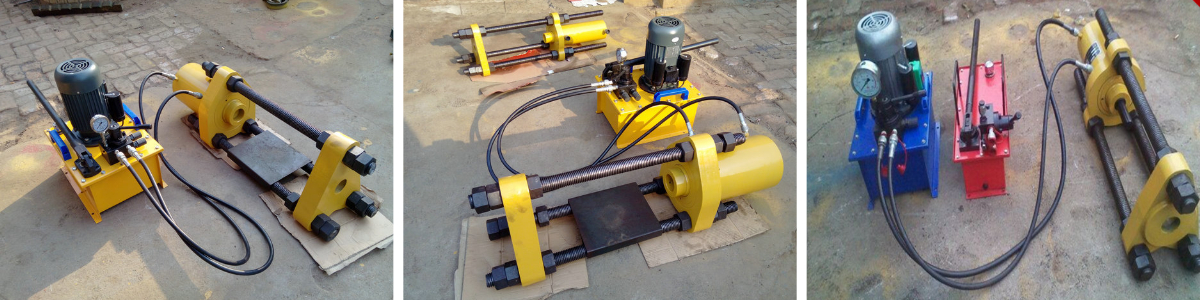

Brief introduction to chain press:

The chain press produced by our company is a special tool for disassembling and assembling crawler pin of crawler excavator based on the principle of transforming hydraulic energy into mechanical energy. The electric pump (220V/380V) of our factory is used as the power source to make the hydraulic cylinder move forward quickly so as to remove the pin shaft smoothly. Instead of gas cutting, manual hammer strike method. Keep track intact and undamaged. It is the ideal special tool for track excavator maintenance and assembly. When first use, the tank must be filled with 46# hydraulic oil before the test machine.

The portable chain press adopts two-way hydraulic device, which reduces the oil path and is easy to maintain. Not only suitable for use in the factory, but also anytime and anywhere to the site, field work. Easy to use and dexterous to operate. The model is divided into electric and manual two kinds, users can choose according to their own actual situation.

Chain press installation and commissioning

1, installation: the main machine and hydraulic control (pump station) for the same size, the machine should pay attention to safety when lifting. The press should be installed on the dry concrete foundation without dust pollution, the worktable part should be installed horizontally, the whole machine is stable without vibration. Then connect the oil cylinder and the oil pipe of the hydraulic control part, adjust the working level of the main engine to work. Due to transportation vibration, check whether the parts are loose and retighten them with relevant tools. The tank is filled with filtered N46 anti-wear hydraulic oil or N46 low condensate hydraulic oil.

2. Test run: fill the pump station oil tank with 46# hydraulic oil before use. Clockwise rotation, turning on the power supply connected to tubing (regardless of the direction of the tubing connections, by pumping station on the reversing valve control oil or oil) all pumping station as A and B mouth manual reversing valve control, such as A is oil outlet is B is in the oil return oil return no oil no pressure, pumping stations and oil cylinder after connection, using manual pump air compressor A few times before put the filler of the valve is opened, Drain the air from the tank. Before starting the electric pump, the motor should be moved 2 ~ 3 times to determine the normal operation. Attention should be paid to whether the rotation direction of the motor is correct. If the reverse 380V voltage pump station, please adjust the two-phase power line. The pressure of the cylinder will not be displayed in the process of moving forward or backward. Only when the heavy object on the top is loaded will the pressure be displayed. The pressure of the system is 63MPA.

Precautions for chain press

1. To install and operate the pressure machine correctly, the three screws must be level and the length of adjustment should be consistent

2, the machine is not allowed to correct the mold in operation;

3. The hydraulic oil is NO. N46 anti-wear hydraulic oil or NO. N46 low condensation hydraulic oil, which is used after 80 ~ 100 mesh screen filtration. The first oil change time is not more than two months, and then the oil change once every six months;

4, the machine should check the oil cleanliness after 200 hours of work, no peculiar smell is required, drop a drop of oil on the white filter paper, no ink stain within the center of the oil mark, otherwise the oil should be changed;

5. The press shall not be overloaded; Shall not be partial load

6. If the system leaks unexpectedly, enough hydraulic oil should be added after eliminating the fault to ensure that the oil level is above 80%.

7. Check the cleanliness of pump station and oil tank regularly, and forbid water, dust and foreign matter to enter the oil tank;

8. If the function is changed, the air in the system should be cleared before it can work;

9, in the test run and work, if there is any abnormal should stop immediately check;

10, pressure for 10 minutes to allow 2.5mpa.

11. When the hydraulic system hits the high pressure, it is strictly forbidden to knock on the parts to avoid the danger of bursting or parts popping up.

12, hydraulic pump station in the process of strengthening the pressure, to pay close attention to the digital changes of the pressure gauge, especially when the piston stroke is almost in place, the highest pressure display 60MPA if in place, immediately hit the reversing valve to the median or other a mouth, do not let the tubing for a long time, the cylinder is in a high pressure state. Otherwise it will shorten the service life of the product!

13, when the pin must pay attention to the surrounding environment, otherwise the pin may be shot wounding.

14. In the process of pressurization, it is found that the top out direction of the pin is deviated, so the pressurization should be stopped immediately and the distance of the bolts on the fixing rod of the mounting seat should be adjusted. Keep the pressure on until it's balanced, so the pin doesn't fly.