Energy-Efficient External Cylindrical Machining : Pick For Green Manufacturing

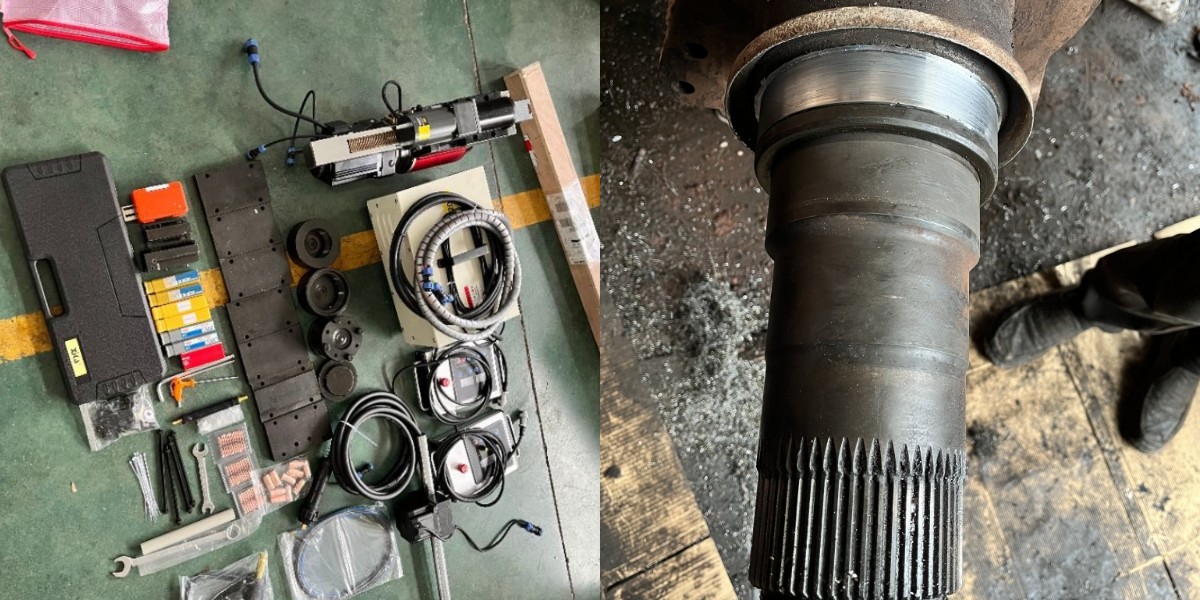

In the global pursuit of carbon neutrality and sustainable development, green manufacturing has become an irreversible trend reshaping the industrial landscape. As a core process in precision component production, Bearing seat external shaft repair machine is undergoing a profound transformation towards energy efficiency. Energy-efficient external cylindrical machining is no longer just an environmental protection measure, but a key strategy for enterprises to enhance competitiveness, reduce operational costs and comply with global environmental regulations. This article explores why it has become the top choice for green manufacturing from three critical perspectives.

1. Policy-Driven Market Transition: Energy-Efficient Machining Becomes a Necessity for Compliance

Data shows that traditional external axis turning machine accounts for 15%-20% of the total energy consumption in the manufacturing industry, making it a key target for energy conservation. Enterprises adopting energy-efficient external cylindrical machining can not only avoid carbon tariffs and environmental penalties but also qualify for government green subsidies and tax incentives, creating a favorable policy environment for sustainable development. For precision component manufacturers targeting global markets, upgrading to energy-efficient external cylindrical machining is no longer an option but a mandatory requirement for compliance and market expansion.

2. Technological Innovation Empowers Green Transformation: The Dual Advancement of Energy Conservation and Precision

The rapid development of intelligent and green technologies has broken the traditional trade-off between machining precision and energy consumption. Energy-efficient bearing seat repair Machine achieves a win-win situation through a series of technological innovations, becoming a core driving force for green manufacturing.

Core energy-saving technologies have been widely applied in external cylindrical machining equipment. The adoption of permanent magnet synchronous spindle motors replaces traditional asynchronous motors, improving energy efficiency by 15%-20% and increasing the power factor from 0.7-0.8 to over 0.95. Intelligent energy management systems, equipped with real-time energy monitoring sensors and edge computing modules, analyze energy consumption curves to optimize machining parameters. For example, in bearing ring machining processes, such systems can automatically recommend optimal speeds, reducing unit product energy consumption by 12% while ensuring machining precision. Additionally, energy recovery technologies, such as regenerative braking energy recovery and spindle waste heat recycling, further improve energy utilization efficiency. In small-part machining with frequent start-stop operations, regenerative braking technology can recover 15%-20% of braking energy, significantly reducing energy waste.

The integration of intelligence and energy efficiency has taken performance to new heights. AI-driven adaptive control systems dynamically adjust energy consumption parameters based on real-time working conditions, while digital twin technology simulates cutting paths to reduce trial cutting times from 5-8 times to 1-2 times, minimizing material waste by 80%. These technological innovations ensure that energy-efficient external cylindrical machining maintains high precision (with roundness error stably controlled within 0.3μm) while achieving significant energy savings, fully meeting the high standards of green manufacturing for both environmental protection and production quality.

3. Economic Value Reconstruction: Energy-Efficient Machining as a Profit Growth Engine

Beyond environmental benefits and policy compliance, energy-efficient bearing seat repair machining creates substantial economic value for enterprises, becoming a new engine for profit growth in the context of rising energy costs.

Direct energy cost savings are substantial. A case study shows that an automotive transmission gear production line using 11kW permanent magnet spindles achieved annual electricity savings of approximately 8,600 kWh per machine, with 50 machines saving over 300,000 yuan in annual electricity costs. For medium-sized mold factories, upgrading to energy-efficient external cylindrical machining equipment can reduce monthly electricity expenses by more than 2,000 yuan, translating to nearly 30,000 yuan in annual savings. Indirect cost reductions are equally impressive: intelligent energy-saving systems reduce equipment failure rates through predictive maintenance, extending the average fault-free operation time by 30% and lowering maintenance costs by about 25%. The extension of cutting tool and coolant service life further reduces consumable costs—for instance, precision cooling systems can extend grinding wheel service life by over 30%.

Conclusion: Embrace Energy-Efficient External Cylindrical Machining to Lead the Green Manufacturing Era

Against the backdrop of global green transformation, energy-efficient external cylindrical machining stands out as a top choice for green manufacturing, driven by policy mandates, technological innovation, and economic value. It not only helps enterprises comply with environmental regulations and reduce carbon footprints but also enhances machining precision, reduces operational costs, and unlocks new market opportunities.